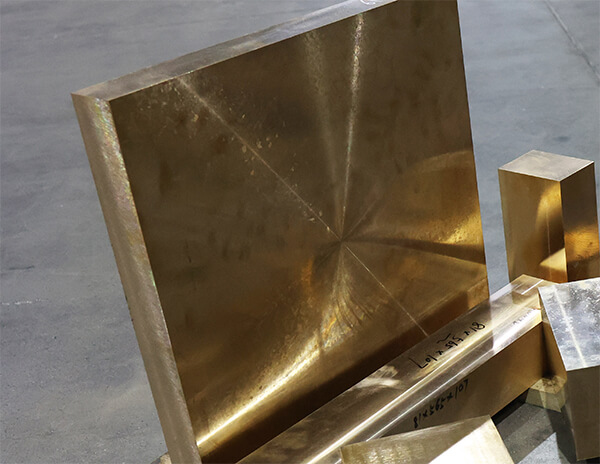

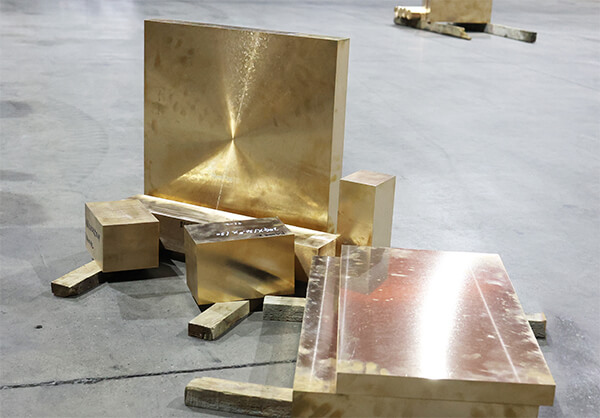

C17000 is a high-performance beryllium copper alloy BeCu, belonging to the grade specified by the American ASTM standard (also known as Alloy 165 or CDA 170). It is renowned for its excellent strength, hardness, electrical conductivity and fatigue resistance, and is widely used in the fields of electronics, aerospace, and mold manufacturing.

The following specifications cover Copper Alloys C17000

· UNS;C17000

· CDA:170

· DIN:CuBe1.7

· EN:BeCu

Chemical composition of C17000 beryllium-copper alloy (typical values)

Beryllium (Be): 1.6 - 1.8%

Cobalt (Co): 0.2 - 0.6% (used to refine grains and enhance performance)

Copper (Cu): The remainder (approximately 97% or more)

Other trace elements: such as nickel, iron, etc. (in trace amounts).

Main characteristics of C17000 beryllium copper alloy

l High strength and hardness: Through solution hardening treatment (heat treatment), the tensile strength can reach 1100 - 1400 MPa, and the hardness can reach HRC 38 - 42.

l Good electrical conductivity: Approximately 22 - 28% IACS (International Annealed Copper Standard), superior to most high-strength alloys.

l Fatigue resistance: Suitable for high-frequency or cyclic load scenarios (such as springs, connectors).

l wear resistance: Used in high-wear environments (such as molds, bearings).

l Non-magnetic: Suitable for electronic and medical equipment.

Physical Properties of C17000 Beryllium Copper Alloy

Elastic Modulus: 19 x 106 psi (131 Gpa)

Density: 0.304 lb/in3 (8.41 g/cm3)

Poisson's Ratio: 0.3

Relative Magnetic Permeability: <1.01

Cu+Be+Co+Ni+Fe: 99.5%min

Electrical Conductivity: 22-30% IACS (12.8-17.5 MS/m)

Thermal Conductivity: 70°F / 20°C - 60 BTU/ft•hr•°F (105 W/m•K)

Coefficient of Thermal Expansion: 9.7 ppm/°F (17.5 ppm/°C)

Heat Capacity: 70°F / 20°C - 0.086 BTU/lb•°F (360 J/kg K)

Heat Capacity: 200°F / 100°C - 0.097 BTU/lb•°F (406 J/kg K)

Melting Range: 1600 - 1800 °F (870 - 980 °C)

Provides a wide range of high performance services across multiple industries and technologies

-

FAQ’s

For quick answers to our customers FAQ’s. -

Quotations

Get the latest and most favorable quotations -

Other informations

Product specifications, catalogues, tests, samples, performance, etc