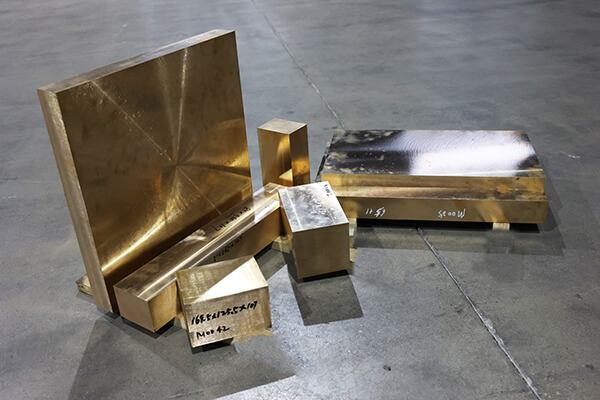

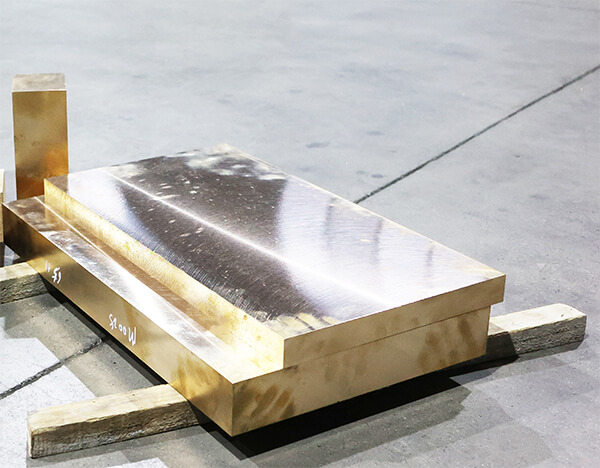

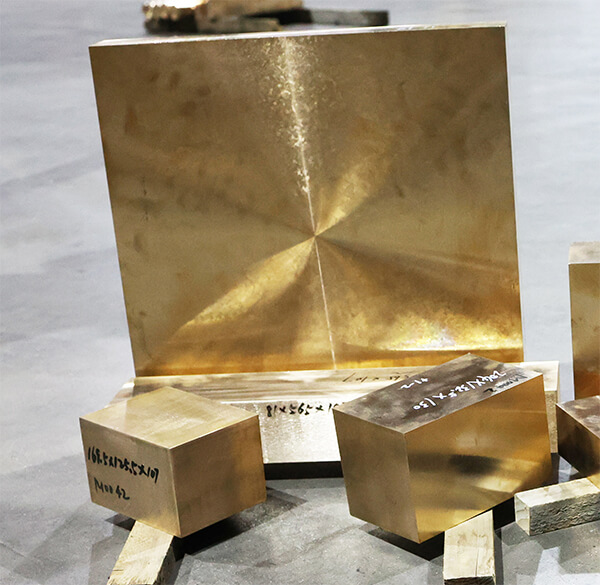

High hardness C17000 beryllium copper plate and high-toughness beryllium alloy copper block

Process: Punching

Molding process: Die casting

Surface treatment process: Polishing

Copper plate width: 10 - 3000mm

Softening temperature: 800 - 1500℃

Product status: Soft, semi-hard, hard, etc.

Specification of High hardness C17000 copper plate

Thickness: 0.1mm - 200mm

Application: Power equipment, for instruments, telecommunications, condensing equipment, etc.

Process: Punching

Molding process: Die casting

Surface treatment process: Polishing

Copper plate width: 10 - 3000mm

Softening temperature: 800 - 1500℃

Product status: Soft, semi-hard, hard, etc.

Strength and Hardness

After aging treatment, the tensile strength of High hardness C17000 beryllium copper plate reaches 1400 MPa (while C17000 is approximately 1310 MPa), and the hardness is HRC 44 (while C17000 has a hardness of HRC 42).

The γ'-CuBe precipitated phase in C17000 is finer (5-15 nm compared to 5-20 nm in C17000), and its strengthening effect is more significant.

Good machinability

The surface of the high hardness C17100 beryllium copper plate is uniform, and it has good pressure processing properties in both cold and hot states.

The hardness of High hardness C17100 beryllium copper plate is significantly affected by the heat treatment state:

Solid solution state: Hardness is approximately HRC 20-25 (corresponding to HB of about 150)

Tempering state: Hardness can reach HRC 35-42 (up to HRC 42), some sources indicate that the hardness can increase by up to 130-350HV after tempering.

Hardness change mechanism

The High hardness C17100 beryllium copper plate is strengthened through the "solution treatment + aging" process:

Solution treatment: held at 790-810℃ for 30 minutes, then rapidly cooled (water quenching)

Aging treatment: held at 315-345℃ for 2-4 hours, the hardness peak occurs in the later stage of aging

Typical application scenarios:

High wear resistance scenarios: such as precision mold inserts, bearing bushings, etc., which require components with high hardness.

Elasticity-demanding scenarios: such as springs, connectors, etc., which need to balance strength and elasticity in structural components.

Leave a Messages