C17000 beryllium copper rod oxygen-free high hardness wear resistant

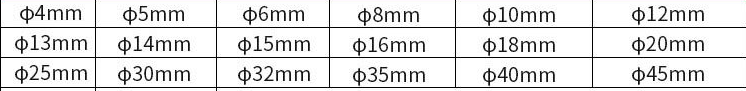

Specification: Φ2.0 - Φ200mm

Tolerance: +10um

Production process: Extrusion

Processing method: Mechanical processing

C17000 is a high-strength beryllium copper alloy, mainly composed of copper and beryllium. It achieves outstanding mechanical properties through precipitation hardening heat treatment. Its key feature is that it maintains excellent conductivity while possessing extremely high strength, hardness, and wear resistance. Additionally, this material also exhibits excellent fatigue resistance, corrosion resistance, and non-magnetism. In terms of shape, C17000 is typically supplied in various forms such as rods, wires, sheets, and tubes to meet different processing requirements. Among them, rods are widely used due to their good mechanical processing properties and comprehensive performance, and are extensively employed in manufacturing components that require both high strength and conductivity, such as springs, diaphragms, explosion-proof tools, and precision switches.

Specification: Φ2.0 - Φ200mm

Tolerance: +10um

Production process: Extrusion

Processing method: Mechanical processing

Characteristics: High strength, corrosion resistance

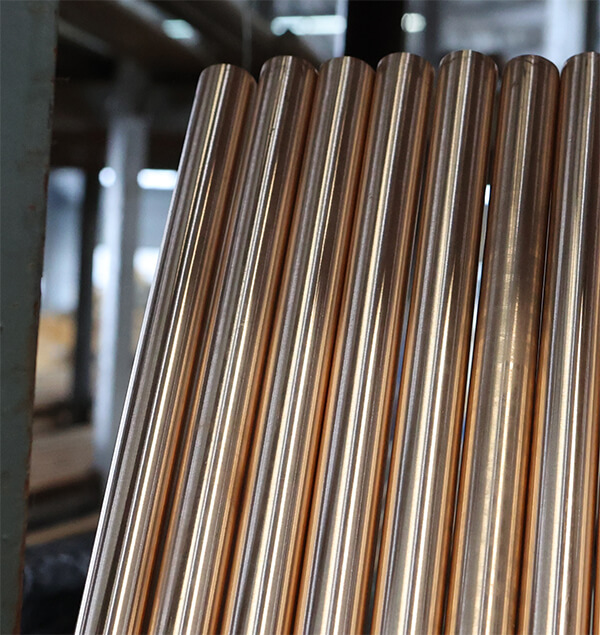

Surface: Smooth

Product application: Manufacturing industries such as construction, machinery, coal mines, chemical industry, power, railway, bridges, petroleum machinery, etc.

The hardness of the C17000 beryllium copper rod

The C17000 beryllium copper, with a beryllium content of 1.6% to 1.79%, achieves an extremely high hardness of HRC 38 to 42. The γ'-CuBe nano-crystalline precipitated phase enables an ultimate tensile strength of 1310 MPa. It is widely used in aviation sealing rings and 5G connectors, maintaining a strength of 500 MPa even at 650℃.

High-quality materials

The C17000 beryllium copper rod has excellent electrical and thermal conductivity, and is easy to be processed under both hot and cold pressures. Sturdy and durable

The C17000 beryllium copper rod has excellent sliding characteristics and a long service life.

Exquisite craftsmanship

The surface of the C17000 beryllium copper rod has undergone strict treatment, ensuring good corrosion resistance and long-lasting durability.

Standard | ASTMB152,B187,B133,B301,B196,B441,B465,JISH3250-2006, |

Material | C17000 beryllium copper |

Size | Diameter:0.8-100mm |

Length:1-2m 1-4m | |

Hardness | 1/16 hard,1/8 hard,3/8 hard,1/4 hard,1/2hard,full hard,soft,etc |

Surface | mill,polished,bright,oiled,hair line,brush,mirror,sand blast,or as required |

Package | Standard export package ,or as required. |

Application | Copper bar is widely used in boat building,War industry, Car industry and communication |

Material Characteristics of C17000 beryllium copper rod

The advantages ofC17000 beryllium copper rod stem from its multi-dimensional properties. In terms of mechanical performance,C17000 beryllium copper rod has a tensile strength comparable to that of steel (up to 1400 MPa), yet it is 30% lighter than steel, and is highly wear-resistant and fatigue-resistant, not deforming under repeated loading. In terms of electrical properties, the conductivity ofC17000 beryllium copper rod is approximately 20-25% of that of pure copper, much higher than that of other high-strength alloys, making it an efficient current carrier. It has excellent thermal stability, with stable performance within the temperature range of -200°C to 250°C, and excellent corrosion resistance, capable of resisting the erosion of seawater and chemicals. Additionally, it is easy to weld and machine, and its surface can be polished to a mirror-like finish.

Leave a Messages