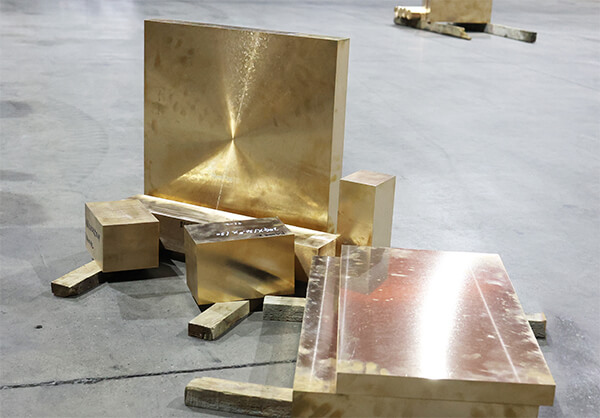

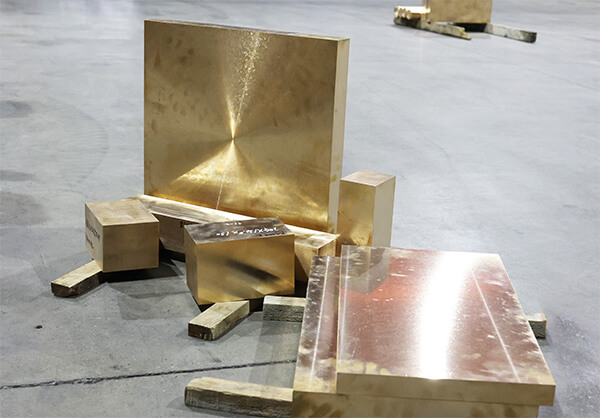

High conductivity C17000 beryllium copper plate with crack resistance

Sales method: Direct sales, wholesale, retail

Goods sales type: Spot

Processing customization: Yes

Softening temperature: 930℃

Specification: 0.1 - 200mm

Usage: Hardware, machinery, molds

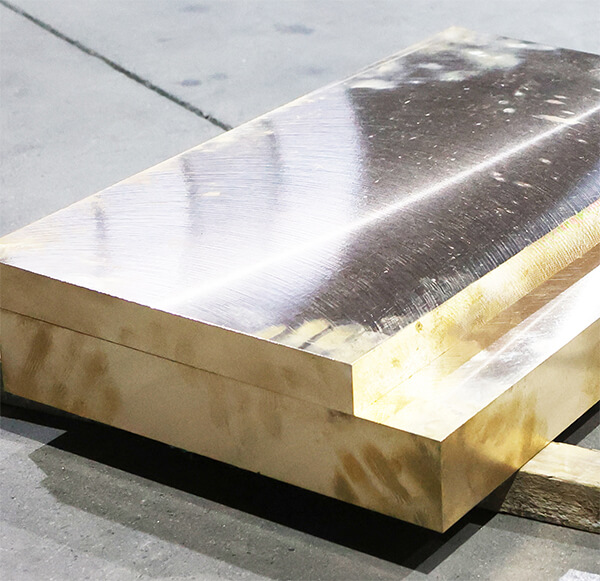

C17000 Beryllium Copper Plate Overview

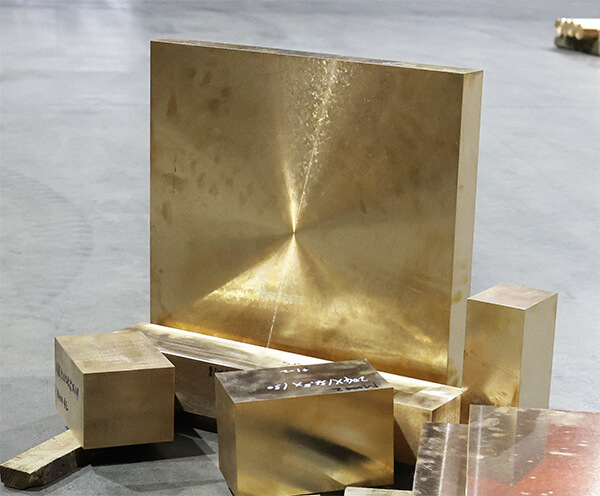

C17000 beryllium copper plate is a high-performance precipitation hardening copper alloy sheet, widely used in high-end manufacturing fields that have strict requirements for conductivity, strength and elasticity.

This material is composed of copper as the base material (with the remainder), and contains 1.60% to 1.79% beryllium (Be) and 0.20% to 0.60% nickel + cobalt (Ni + Co) as the main strengthening elements. After solution treatment and aging heat treatment, it can achieve tensile strength of up to 1105 to 1345 MPa, hardness of HRC 38 to 44, while maintaining a high conductivity of 18% to 22% IACS and excellent thermal conductivity of approximately 105 W/(m·K).

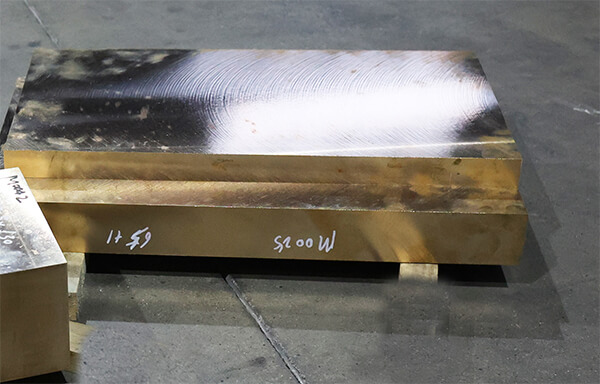

C17000 beryllium copper plates are usually supplied in rectangular sheet form, with thickness ranges covering 0.5 to 80 mm, width up to 3 meters, and length up to 6 meters. They can also be customized with ultra-thin strips (starting from 0.05 mm) or large-sized thick plates according to customer requirements.

The non-magnetic, corrosion-resistant, and spark-free characteristics of C17000 beryllium copper plates make them ideal materials for key components such as electronic connectors, 5G communication devices, aerospace sensors, precision mold inserts, and explosion-proof tools.

Performance: Wear-resistant

Copper content (%): 97

Sales method: Direct sales, wholesale, retail

Goods sales type: Spot

Processing customization: Yes

Softening temperature: 930℃

Specification: 0.1 - 200mm

Usage: Hardware, machinery, molds

Product Specifications: Customizable

Product Packaging: Wooden crates, wooden supports, cardboard boxes

Product Features: Smooth surface, strong toughness, corrosion-resistant, resistant to high pressure

Product Applications: Metallurgy, electronic communication, automotive manufacturing, precision molds and other fields

Product features

Has good electrical conductivity/thermal conductivity and processing performance

The electrical and thermal conductivity of C17000 beryllium copper plate

The electrical conductivity reaches 20-28% IACS (International Annealed Copper Standard), and the thermal conductivity is 105-120 W/(m·K), which is much higher than that of stainless steel and titanium alloys. It is suitable for high-current or heat dissipation scenarios.

The material is widely used in various industries such as aviation and aerospace, shipbuilding, mechanical equipment, mold manufacturing, electronic and electrical, hardware products, handicrafts, etc.

C17000 beryllium copper (CuBe2) has high electrical conductivity, with its aged state conductivity reaching 20%-22% IACS (International Annealed Copper Standard), maintaining high strength while also having good electrical properties.

Electrical conductivity characteristics

C17000 beryllium copper, by adding elements of beryllium (1.6%-2.0%) and nickel (0.2%-0.6%), maintains a high electrical conductivity even after aging hardening treatment. This material is widely used in 5G base stations, new energy vehicles, and other fields that have high requirements for electrical conductivity and strength.

Leave a Messages