Why is beryllium copper so expensive?

.jpg)

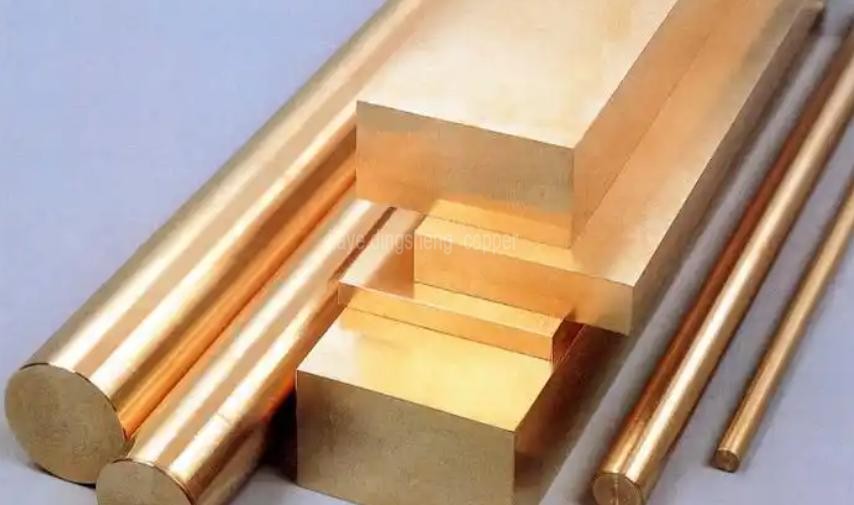

The reason why beryllium copper (abbreviated as BeCu) is expensive is determined by the scarcity of its raw materials, complex manufacturing process, high technical threshold, strict safety and enviro···

How can chromium zirconium copper welding joints avoid thermal cracking?

How to prevent thermal cracking in chromium-zirconium-copper welded joints - Detailed measuresThe main causes of hot crackingLow-melting-point eutectics and impurity segregationDuring the welding of c···

What does beryllium do to copper?

Beryllium (Be), as a key alloying element in copper alloys, exerts significant and diverse strengthening and functionalization effects on the copper (Cu) matrix. Its core role is manifested in the enh···

What is the effect of alloying tin to copper?

Adding tin to copper (forming copper-tin alloy, or bronze) significantly alters the various properties of copper and is widely used in industry and daily life. Here is a summary of the detailed effect···

Is copper harder to weld than aluminum?

The welding of copper and aluminum has distinct difficulties. However, considering factors such as process complexity, defect tendencies, and equipment requirements, aluminum welding is generally cons···