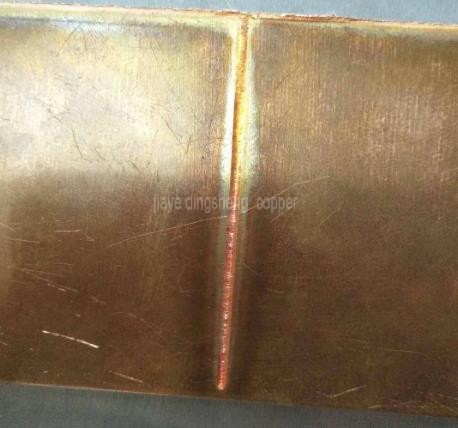

How can chromium zirconium copper welding joints avoid thermal cracking?

How to prevent thermal cracking in chromium-zirconium-copper welded joints - Detailed measures

The main causes of hot cracking

Low-melting-point eutectics and impurity segregation

During the welding of chromium-zirconium-copper, oxygen reacts with copper to form Cu₂O, which forms a low-melting-point eutectic (with a melting point of approximately 1064°C) along with α-copper. Lead and other impurities are also prone to form low-melting-point eutectics, causing intergranular liquid films to crack under the action of stress.

Gases such as hydrogen can also cause cracks in the weld seam.

High thermal conductivity and thermal stress

Chromium-zirconium copper has excellent thermal conductivity (8 times that of carbon steel). Welding requires a concentrated heat source, resulting in large local temperature differences and significant thermal stress, which can easily cause thermal cracking.

Improper process control If the process factors such as weld shape, restraint stress, and cooling rate are not properly controlled, it will also intensify the tendency of hot cracking.

II. Specific Measures to Avoid Hot Cracking

1. Metallurgical Measures (Material and Welding Material Control)

Strictly limit the impurity content

Control the content of harmful impurities such as S, P, Pb in the base metal and welding wire, and preferentially select high-purity materials to avoid the formation of low-melting-point eutectics.

Select appropriate welding wire

Prioritize the use of special welding wires containing deoxidizing elements (such as Si, Mn), such as wire 201, wire 202 or brass welding wire (such as Weioudin 204S), which can reduce the tendency of pores and cracks by 718.

Avoid hydrogen sources

Thoroughly clean the surface of the weldment and welding wire of oil and oxides before welding to prevent hydrogen-induced cracking 23.

2. Welding Process Measures

Preheating before welding

Crucible copper welding must be preheated, with a general preheating temperature of 300–500℃, and for thick pieces, 400–500℃ can be selected, to reduce thermal stress and slow down the cooling rate.

Rational selection of welding methods

Recommended method: TIG (Tungsten Inert Gas Arc Welding) is the first choice, with good protection atmosphere, suitable for thin plates; for thick pieces or high-precision occasions, electron beam welding or laser welding can be used.

Energy concentration: Use a concentrated welding heat source to ensure the molten pool reaches the melting point quickly and reduces the heat affected zone.

Welding parameter control

Adopt the principle of "short arc, fast welding speed, small current" to avoid overheating, control the weld depth, and the recommended weld width-to-depth ratio is 1–1.4921.

When performing multi-layer welding, pay attention to interlayer cleaning, control the weld depth, and prevent the accumulation of thermal stress.

Welding sequence and stress control

Use symmetrical welding, step-back welding method, etc., to disperse the welding stress and avoid excessive constraint stress.

Try to weld under a smaller stiffness condition to reduce the constraint degree.

3. Structural Design and Joint Treatment

Joint form optimization

Try to use butt joints, surface overlay welding, etc., which have higher crack resistance, and avoid T-joints, lap joints, etc., which are stress concentration forms.

Groove and assembly gap control

The joint gap should be ≤ 0.4mm, without bevels or small bevels, to avoid excessive molten pool and stress concentration.

4. Post-Welding Treatment

Hammering and slow cooling

After welding, gently strike the weld seam with a flat hammer to release stress; the workpiece should be slowly cooled to avoid rapid cooling leading to residual stress.

Aging heat treatment (recommended)

Perform aging heat treatment after welding (such as 480–520℃ for 300–400 minutes), which can restore and enhance the mechanical properties of the joint and reduce residual stress.

III. Notes and Best Practices

Environment and Cleanliness

The welding environment should be dry and free of wind to prevent oxidation. Before welding, the weldment and the welding wire must be thoroughly cleaned using mechanical or chemical methods.

Avoid Overheating

Overheating can cause the loss of alloy elements, coarse grain formation, and increase the risk of hot cracking. The welding line energy should be controlled, and small welding specifications should be adopted.

Process Testing

For important structures, it is recommended to conduct process tests first to verify the reliability of the welding materials, parameters, and process combination.

IV. Example of Reference Process (Electron Beam Welding)

Pre-welding heating: Voltage 60–70 kV, Current 4–6 mA, Beam current for seam 3–4 mA, Focused beam current 260–270 mA. Preheat the weld seam and the 5mm area on both sides first.

Welding parameters: Voltage 60–70 kV, Current 45–50 mA, Welding speed 90–100 mm/min, Joint gap ≤ 0.4 mm.

Post-welding aging: Hold at 500°C for 360 minutes, then cool in the furnace.

Conclusion

The key to avoiding thermal cracking in chromium-zirconium-copper welded joints lies in:

strict control of impurities, rational selection of welding materials, adequate preheating, concentrated welding process, reasonable structural design, and post-weld heat treatment.

It is recommended to use TIG or electron beam welding, combined with preheating at 300–500℃ and aging heat treatment, which can effectively prevent thermal cracking and achieve high-performance joints.

# Tags:

-

chromium zirconium copper welding joints avoid thermal cracking

.jpg)