Is copper harder to weld than aluminum?

The welding of copper and aluminum has distinct difficulties. However, considering factors such as process complexity, defect tendencies, and equipment requirements, aluminum welding is generally considered to be more challenging than copper welding. The following provides a detailed comparison from multiple perspectives:

Physical and chemical property comparison

Characteristics | Copper | Aluminum |

Melting point | 1083℃(high) | 660℃(low) |

Thermal conductivity | Extremely high (about 8 times that of steel) | High (about 4 times that of steel) |

Coefficient of thermal expansion | Lower | High (about 2 times that of steel) |

Oxide film | Copper oxide is easy to remove and has a low melting point | The melting point of alumina is 2050℃, and it is extremely difficult to remove |

Hydrogen porosity tendency | Lower | Extremely high (the amount of hydrogen dissolved in liquid aluminum is large) |

Thermal cracking tendency | Lower | High (high shrinkage rate, prone to generating hot cracks) |

Comparison of Welding Process Difficulties

1. Copper Welding Difficulties

High thermal conductivity: Heat dissipates rapidly, requiring a high-power heat source or preheating.

High reflectivity: The reflectivity of laser welding can reach up to 95%, making it difficult to initiate melting.

Oxide film: The surface is prone to oxidation, but the melting point of copper oxide is low, making it relatively easy to remove.

Air holes and cracks: Hydrogen pores and thermal cracks are prone to occur, but they are lighter than aluminum.

2. Aluminum Welding Difficulties

High oxide film: The melting point of aluminum oxide is extremely high, hindering fusion and requiring mechanical or chemical removal.

Hydrogen pores: Liquid aluminum has a large hydrogen solubility, and air holes are prone to form during cooling.

Thermal deformation and cracks: The high thermal expansion coefficient makes it prone to deformation and thermal cracking.

No color change: The color of the molten pool does not change, making it difficult to determine the temperature.

High equipment requirements: Special welding machines (such as AC TIG, pulsed MIG) are required, along with strict environmental control.

Comprehensive Comparison Table

Challenges | Copper | Aluminum |

Meltability | Requires high power but with stable molten pool | Melts easily, but the molten pool is unstable. |

Oxide film treatment | Relatively easy | Extremely difficult. Must be completely removed. |

Porosity tendency | Medium | Extremely high |

Crack tendency | Low | high |

Welding equipment requirements | High power, resistant to high reverse laser, etc. | Exchange TIG, pulsed MIG, dry environment, etc. |

Operational experience threshold | Medium | high |

Welding of dissimilar metals | The welding of copper and aluminum of different materials is extremely difficult | The welding of copper and aluminum of different materials is extremely difficult. |

Industry Experience Summary

Copper Welding: High requirements for equipment power and heat dissipation, but issues such as oxide films and pores are relatively controllable. Suitable for high-power lasers, TIG, etc.

Aluminum Welding: Extremely high requirements for pre-weld cleaning, environmental humidity, and weld machine functions (such as cathode cleaning). Novices are prone to pores, cracks, and incomplete fusion.

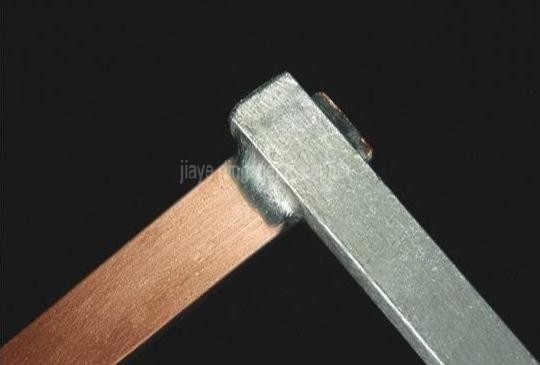

Copper-Aluminum Mixed Welding: More difficult than welding copper or aluminum alone. Common issues include brittle intermetallic compounds (such as CuAl2), interface cracks, and pores. Special processes (welding by brazing, diffusion welding, ultrasonic welding) are required.

Conclusion

The welding of aluminum is generally more difficult than that of copper, mainly due to the extremely difficult removal of oxide films, high tendency of pores and hot cracks, and strict requirements for the environment and equipment. Although copper welding requires a large power heat source, the overall defect control and process stability are better than those of aluminum.

The welding of dissimilar metals of copper and aluminum is a more challenging task, and special fluxes, transition layers or solid-state welding methods are often required.

Practical suggestions

If welding copper: prefer high-power laser, TIG or MIG, and pay attention to preheating and gas protection.

If welding aluminum: the surface must be cleaned strictly, the environmental humidity must be controlled, AC TIG or pulsed MIG should be selected, and gas protection should be strengthened.

If welding copper and aluminum: recommend brazing, diffusion welding or ultrasonic welding, and avoid direct fusion welding.

# Tags:

-

Is copper harder to weld than aluminum