Phosphor bronze plates easy to machining and wear resistance

Width: 10 - 400mm

Length: 300 - 600mm

Thickness: 10 - 100mm

Flatness tolerance: ≤ 0.3mm/m

Tin content: 6.0 - 11.0%

Phosphorus content: 0.1 - 0.5%

Width: 10 - 400mm

Length: 300 - 600mm

Thickness: 10 - 100mm

Flatness tolerance: ≤ 0.3mm/m

Tin content: 6.0 - 11.0%

Phosphorus content: 0.1 - 0.5%

Type: Copper alloy profiles

Production method: Drawing

Shape: Circular, Square

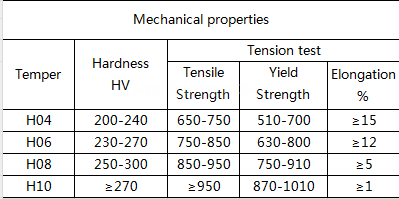

The processing properties of phosphor bronze plate

Phosphor bronze sheet is easy to be machined. It is a copper alloy containing phosphorus and has excellent processing properties. Its material has moderate hardness, good ductility and high toughness, and is not prone to fracture during machining and forming. In addition, phosphor bronze sheet is also easy to undergo hot processing and welding.

Phosphorus bronze plate with a tin content of about 5.0%. This alloy phosphorus bronze plate has high elasticity, strength, wear resistance, high temperature resistance, stress relaxation resistance, and corrosion resistance. phosphorus bronze plate can be used to manufacture new energy vehicle connectors, wiring terminals, stamping parts, elastic connectors, etc.

Phosphor Bronze Plate Composition

Phosphor bronze is a type of phosphorus-containing brass. Its typical composition consists of copper, zinc and phosphorus, with the phosphorus content usually ranging from 0.01% to 0.5%. The specific composition table is as follows:

Copper (Cu): Minor amount

Zinc (Zn): 60% - 90%

Phosphorus (P): 0.01% - 0.5%

Other trace elements: iron (Fe), lead (Pb), tin (Sn), etc.

The mechanical processing performance of phosphor bronze

The mechanical processing performance of phosphor bronze sheets that is easy to machine is extremely excellent. It is easy to carry out cutting, drilling, milling and other processing operations. During these processing procedures, the chips of phosphor bronze are easy to peel off and will not clog the cutting tools, thus resulting in higher processing efficiency and better surface quality. At the same time, the surface finish of phosphor bronze after processing is high, and it is less likely to produce burrs, oxidation and other problems, so it is very suitable for manufacturing precision parts or decorative parts.

Leave a Messages