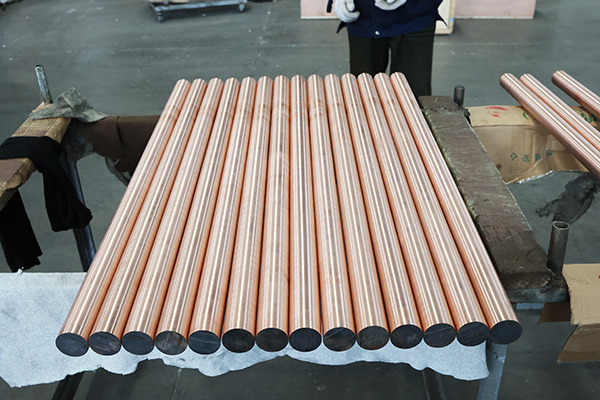

High strength C18150 chromium zirconium copper rod with high hardness

Tensile strength: ≥ 380

Cross-sectional shape: Circular

Specification: Φ10 - Φ110

Features: High corrosion resistance

Copper content: 99.95% - 99.98%

Processing services: Cutting, flattening, polishing, etc.

Hardness: 110 - 145HV

Application: Welding in the mechanical manufacturing industry

Tensile strength: ≥ 380

Cross-sectional shape: Circular

Specification: Φ10 - Φ110

Features: High corrosion resistance

Copper content: 99.95% - 99.98%

Processing services: Cutting, flattening, polishing, etc.

Physical and mechanical strength properties of C18150 chromium zirconium copper rod

l High strength: The tensile strength can reach 450-550 MPa, significantly higher than pure copper (about 200 MPa), approaching the level of certain low-alloy steels.

l High hardness: After heat treatment, the hardness can reach 120-150 HV, with excellent wear resistance.

l Good ductility: elongation rate of 8% - 15%, with the ability for plastic processing.

l High-temperature stability: It can maintain over 80% of its room temperature strength even at temperatures ranging from 400 to 500 degrees Celsius.

Good processing performance of C18150 chromium zirconium copper rod

The high-strength C18150 chromium-zirconium copper rod has excellent plasticity and is easy to be cold and hot formed; cast copper alloys have good casting performance.

Having certain special mechanical properties of C18150 chromium zirconium copper rod

For example, excellent anti-friction and wear resistance (such as bronze and some brass), high elastic limit and fatigue limit (such as beryllium bronze, etc.).

C18150 chromium zirconium copper rod Product specification

Product Name | C18150 chrome-zirconium copper rod |

Length | 100mm-3000mm |

Processing Service | Bending, Welding, Decoiling, Cutting, Punching |

Application | Widely used in automobile, motorcycle, barrel (tank) and other machinery manufacturing industry welding, conductive nozzle, switch,contact, mold block, welding machine auxiliary devices for various materials. |

Material | C18200 C18400 C18150 |

Standard | JIS ASTM DIN EN ISO |

Type | Round Straight Rod/Square bar |

MOQ | 1 Kilograms |

Hardness | 1/4H 1/2H 3/4H |

Payment Term | 100% visa, mastercard, T/T |

PRICE TERM | CIF CFR FOB Ex-Work |

Leave a Messages