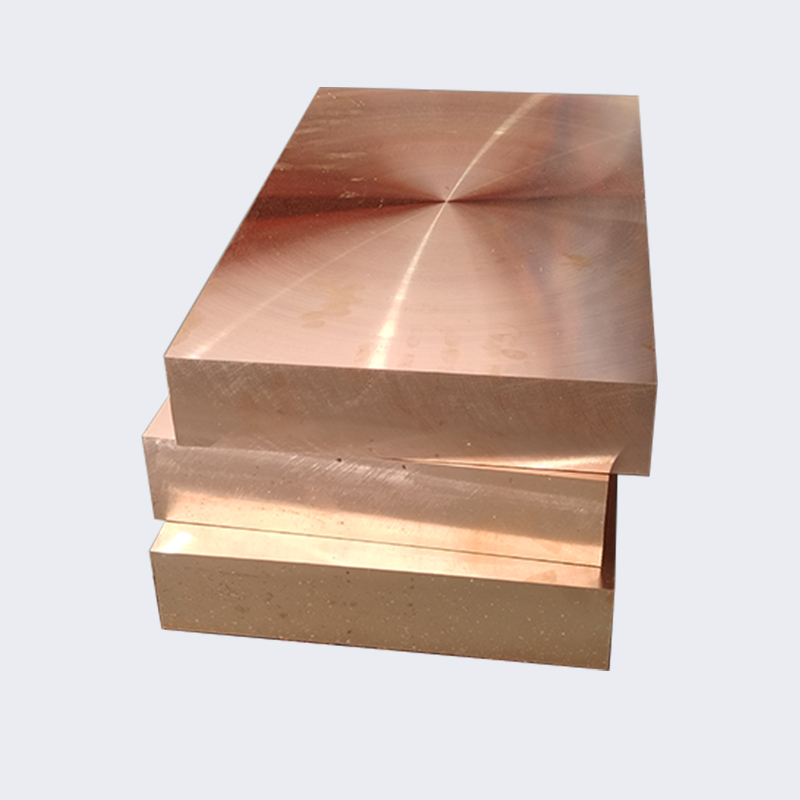

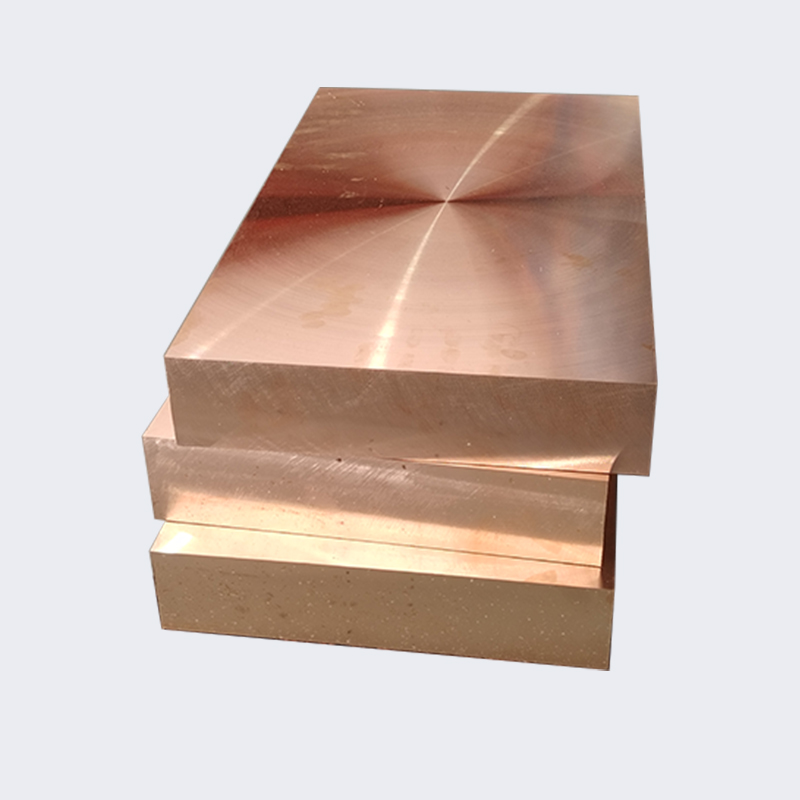

High strength C18000 nickel chromium copper plate for mechanical components

Nickel: 2.0% - 3.0%

Surface treatment: Polished

Tensile strength: Above 450 MPa

Yield strength: 350 MPa

Elongation: 15% - 20%

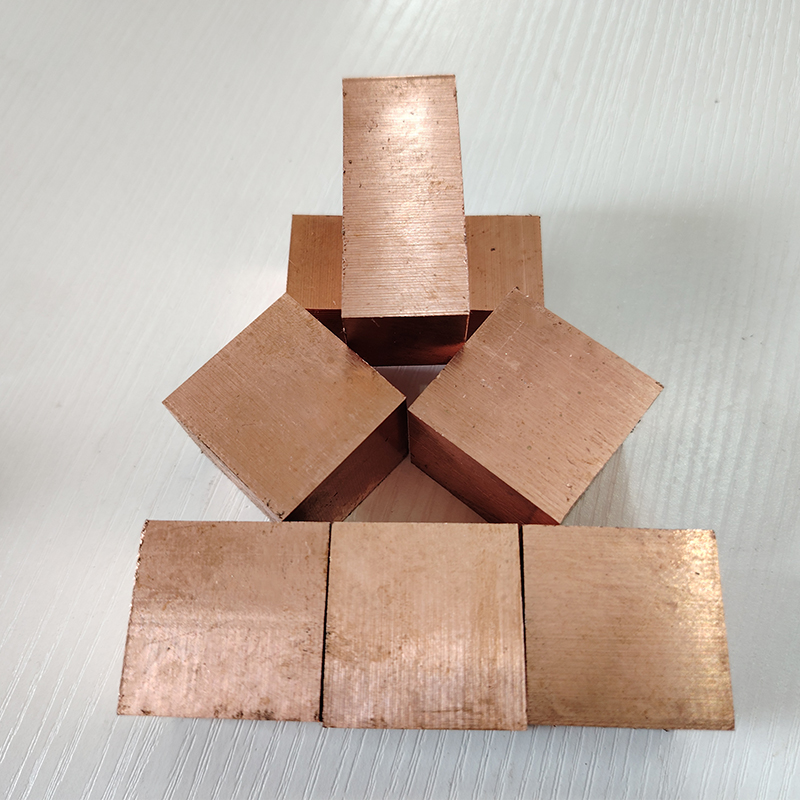

Product specifications: Customizable

Nickel: 2.0% - 3.0%

Surface treatment: Polished

Tensile strength: Above 450 MPa

Yield strength: 350 MPa

Elongation: 15% - 20%

Product specifications: Customizable

Product packaging: Wooden boxes, wooden pallets, paper boxes

Product features: Smooth surface, strong toughness, corrosion-resistant, resistant to high pressure

Product applications: Metallurgy, electronic communication, automotive manufacturing, precision molds, etc.

Meanwhile, through alloying and heat treatment processes, the C18000 nickel-chromium copper plate has high strength, capable of withstanding greater loads and stresses. The C18000 nickel-chromium copper plate is suitable for applications that require high-strength materials.

Strength characteristics of nickel-chromium alloys

The high strength of the C18000 nickel-chromium copper plate mainly results from the interaction of its alloying elements. The nickel element can enhance the toughness and ductility of the alloy, while the chromium element can increase the hardness and corrosion resistance of the alloy. When these two elements are combined in a certain proportion, it can significantly improve the overall mechanical properties of the alloy. According to professional data, the tensile strength of certain nickel-chromium alloys can reach 900-1200 MPa, which is much higher than the strength of general metal materials.

In addition, the strength of nickel-chromium alloys is also affected by the heat treatment process. Through reasonable heat treatment, the C18000 nickel-chromium copper plate can further adjust the internal structure of the alloy, eliminate internal stress, and improve the strength and toughness of the alloy.

Leave a Messages