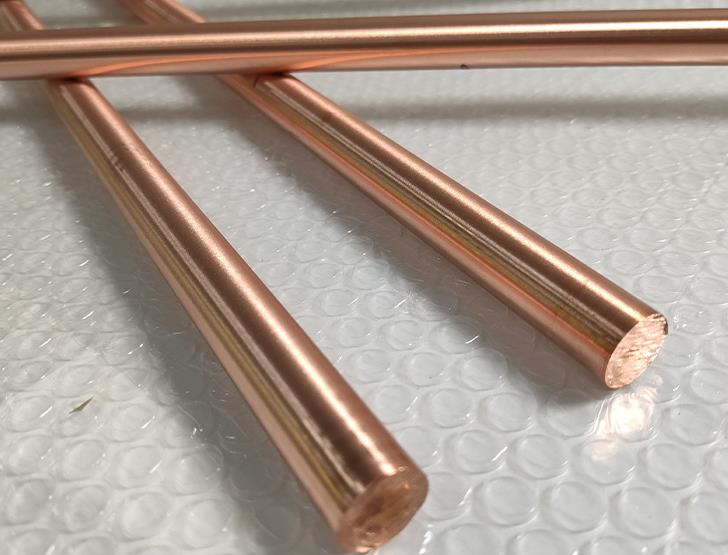

C17510 beryllium copper rod high thermal conductivity high temperature resistance beryllium copper

Softening temperature: 1180

Characteristics: Lead-free and environmentally friendly

Type: Copper bar material

Product specifications: Φ0.8 - Φ200mm

Length: 1000mm - 2500mm

C17510 beryllium copper rod is a high-performance beryllium-copper alloy. By adding appropriate amounts of elements such as beryllium, cobalt, and nickel to copper and undergoing precipitation hardening heat treatment, fine precipitates are formed within the material, endowing it with outstanding comprehensive properties. Its most notable feature is that it combines excellent electrical conductivity with extremely high mechanical strength, making it one of the strongest materials among conductive copper alloys. Additionally, it possesses excellent hardness, wear resistance, fatigue resistance, and good corrosion resistance. The material itself is non-magnetic and maintains stable performance even at high temperatures. In terms of form, C17510 is mainly supplied in the form of rods, with its diameter and length customizable according to customer requirements, facilitating machining processes such as turning and milling. Apart from rods, this alloy is also commonly produced in various forms such as sheets, strips, wires, and tubes to meet the processing needs for complex components in different industrial fields.

Softening temperature: 1180

Product characteristics: Lead-free and environmentally friendly

Type: Copper bar material

Product specifications: Φ0.8 - Φ200mm

Length: 1000mm - 2500mm

Performance: Strong conductivity

Product specifications: Customizable as per demand

Process: Vacuum fusion infiltration method

Forming process: Pressing, sintering

Surface treatment process: Grinding, turning

Does it support customization? Yes

Is it a manufacturer's product? Manufacturer direct sales

Advantages: Excellent thermal and electrical conductivity processing performance

Applications: Suitable for manufacturing precision instruments, parts for ships, automotive accessories, etc.

Product Characteristics

High-strength elasticity

Highly elastic with high strength, wear-resistant and durable.

Good electrical conductivity

Excellent electrical conductivity, no magnetism, no sparks generated during impact.

Good corrosion resistance

Extremely resistant to corrosion in air, fresh water and seawater.

Application Domains

Explosion-proof tools

Suitable for manufacturing explosion-proof tools, safe and reliable.

Mold manufacturing

Can be used for various mold manufacturing, extending service life.

Undersea cables

An indispensable material for the construction of undersea cable repeaters.

The high thermal conductivity C17510 beryllium copper rod has excellent electrical and thermal conductivity, good plasticity, and is easy to be hot-pressed and cold-pressure processed. It is used to manufacture products requiring electrical conductivity, such as wires and cables.

The electrical conductivity and thermal conductivity of the high thermal conductivity C17510 beryllium copper rod are second only to silver. It is used to make electrical and thermal conductive devices. Purple copper has good corrosion resistance in air and seawater, and is used in the chemical industry. In addition, the high thermal conductivity C17510 beryllium copper rod has good weldability and can be processed by cold and hot plasticity to produce various semi-finished products and finished products.

Leave a Messages