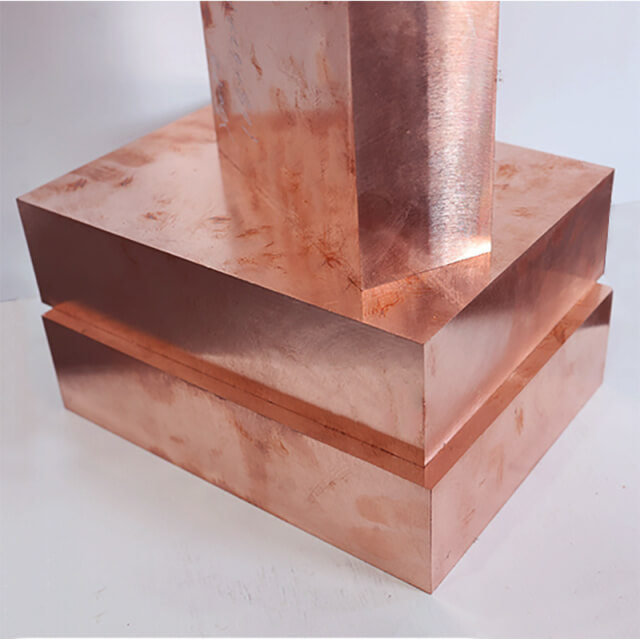

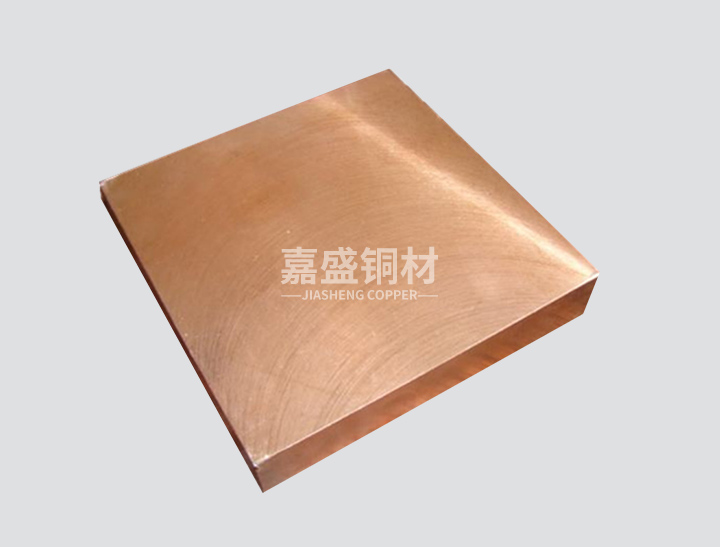

Hot runner system C17500 beryllium copper plate with high conductivity and high resistance electrode

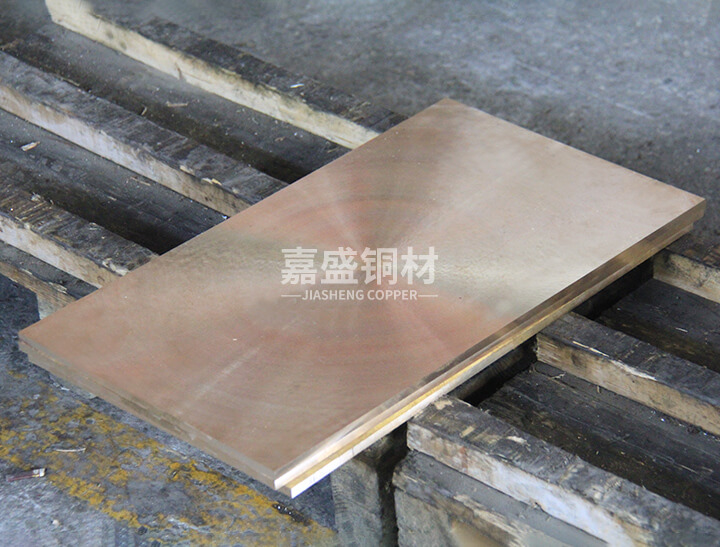

Usage: Mold inserts, resistance welding electrodes, injection molds

Hardness: 36 - 42 HRC

Thermal conductivity: ≥ 225% W/M at 20°C

Softening temperature: 870 - 980°C

Density: 8.85 g/cm³

Usage: Mold inserts, resistance welding electrodes, injection molds

Copper Cobalt Beryllium Alloy CuCo2Be C17500 | |

Material | Be,Cu,Co,Ni,Si,Fe,Al |

Grade | CuBe2 C17200 |

Tensile strength (Mpa) | 1105 |

Density (g/cm3) | 8.83 |

Softening temperature (℃) | 930 |

Hardness (HRC) | 38-44 |

Thermal conductivity (W/m.k20℃) | 105 |

Conductivity (IACS%): | 18 |

High hardness, resistant to wear

Good thermal and electrical conductivity, high softening temperature

Less electrode loss and faster welding speed during welding

Application of Heat Flow Channel C17500 Beryllium-Cobalt-Copper Plate: Beryllium-Cobalt-Copper C17500 is widely used in manufacturing heat flow channels for injection molds or inserts and cores in steel molds. When used as a heat flow channel insert in plastic molds, the heat flow channel C17500 beryllium-cobalt-copper plate can effectively reduce the temperature in the heat concentration area, simplify or eliminate the design of cooling water channels.

The thermal conductivity of cobalt-copper is approximately 34 times better than that of mold steel. This characteristic ensures that plastic products are cooled quickly and uniformly, reducing deformation of the products, unclear shape details and similar defects. In most cases, it can significantly shorten the production cycle of the products. Therefore, the heat flow channel C17500 beryllium-cobalt-copper plate can be widely applied in molds, cores, inserts that require rapid and uniform cooling, especially with high thermal conductivity, corrosion resistance and good polishing requirements.

Beryllium copper is widely used in hot runner cooling systems. Its high thermal conductivity helps to dissipate heat quickly and maintain stable mold temperature.

Mechanical Property:

Grade | Strength of extension(MPA) | Yield Strength (0.2% MPA) | Elongation(106psi) | Hardness(HRC) | Conductivity (IACS%) | Density(g/cm3) | Heat conductivity (W/m.k20℃) |

C17000 | 1105 | 1035 | 19 | 36-42 | 18 | 8.3 | 105 |

C17200 | 1070 | 1000 | 19 | 26-32 | 25 | 8.6 | 120 |

C17500 | 1050 | 1000 | 20 | 36-42 | 50 | 8.85 | 235 |

Leave a Messages