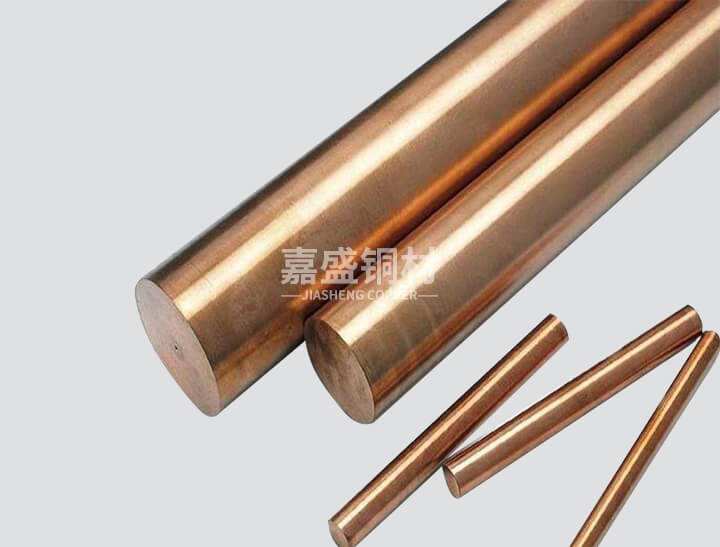

C17500 beryllium copper round rod with highly corrosion-resistant and highly conductive

Usage: Manufacturing components

Tolerance: 0.02mm

Diameter: 1.0mm - 520mm

Length: 3.0mm - 6000mm

Surface: Smooth, no pitting

Beryllium (Be): 0.4% - 0.7%

C17500 beryllium copper rod is a high-performance copper alloy material, presenting a standard cylindrical shape. It can also be customized into square rods, hexagonal rods and other irregular cross-sections according to customer requirements. Its main components are copper (Cu) and a small amount of beryllium (Be, with a content of approximately 0.2% to 0.6%), supplemented by trace elements such as nickel and cobalt. After solution treatment and aging strengthening, it possesses excellent comprehensive properties. C17500 beryllium-copper rod has high strength, high conductivity (up to 45%–50% IACS) and good thermal conductivity. At the same time, it also has excellent fatigue resistance, corrosion resistance and non-magnetic properties. This material can maintain stable performance in high-temperature or high-stress environments and is widely used in electronic connectors, relay spring clips, switch contacts, mold inserts and aerospace precision components, etc. Due to its strong machinability, it is easy to be turned, milled and cold-drawn formed, and has good dimensional stability after heat treatment. It is an ideal alternative to traditional phosphor bronze or stainless steel in high-end manufacturing. C17500 beryllium-copper rod complies with international standards such as ASTM B194 and AMS 4535, meets the high requirements of the industrial environment for the reliability and lifespan of the material, and is a key basic material for improving product performance and market competitiveness.

Usage: Manufacturing components

Tolerance: 0.02mm

Diameter: 1.0mm - 520mm

Length: 3.0mm - 6000mm

Surface: Smooth, no pitting

Beryllium (Be): 0.4% - 0.7%

Product specifications: Customizable, size specifications can be customized

Product features: Good conductivity, good processing performance

Application: Used for manufacturing precision instruments, parts for ships, auto parts, etc.

Standard | ASTM, AISI, JIS, DIN, GB, EN |

Length | 1-4m or as required |

Diameter | 3-200mm |

Surface | Mill finish, polished, anodizing, brushing, sand blasting, powder coating,etc |

C17500 beryllium-copper round bar is a beryllium-copper-based alloy with high strength, hardness, elastic limit and fatigue limit. The corrosion rate of C17500 beryllium-copper round bar in seawater is 1.1 - 1.4 mm/year, and the corrosion depth is 10.9 - 13.8 mm/year. Therefore, it can maintain a long service life even in harsh environments.

C17500 exhibits outstanding performance in various corrosive environments:

In atmospheric and freshwater conditions: Its corrosion resistance is superior to that of copper. After long-term use, there is no significant oxidation of C17500 beryllium copper rods.

In seawater environment: C17500 beryllium copper rods are resistant to intergranular corrosion and impact corrosion, suitable for marine engineering equipment.

In chemical media: It can withstand dilute acids and phosphoric acid corrosion, but C17500 beryllium copper rods should avoid contact with strong corrosive solutions such as nitric acid and ammonia water.

Leave a Messages