C17500 beryllium copper CuCo2Be - Alloy 10 (CDA 175)

The C17500 beryllium copper has a core alloy (Alloy 10)composed of 0.4% - 0.7% beryllium and 1.4% - 2.7% cobalt. The tensile strength of C17500 beryllium copper reaches 1100 MPa, and its conductivity is 45% - 50%. It is an ideal material for precision components such as electronic connectors and aviation springs.

Basic Properties of C17500 Beryllium Copper

Alloy Type: Precipitation-hardening copper-beryllium alloy 10

Common Standards:

US UNS Number: C17500

Chinese National Standard (GB): QBe1.7

International Standard ISO: CuCo2Be

European Standard EN: CuCo2Be (CW101C)

Japanese JIS: C1750

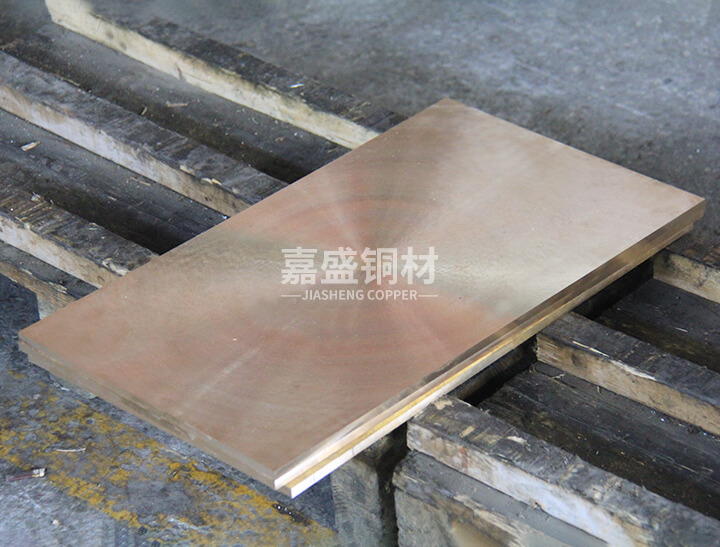

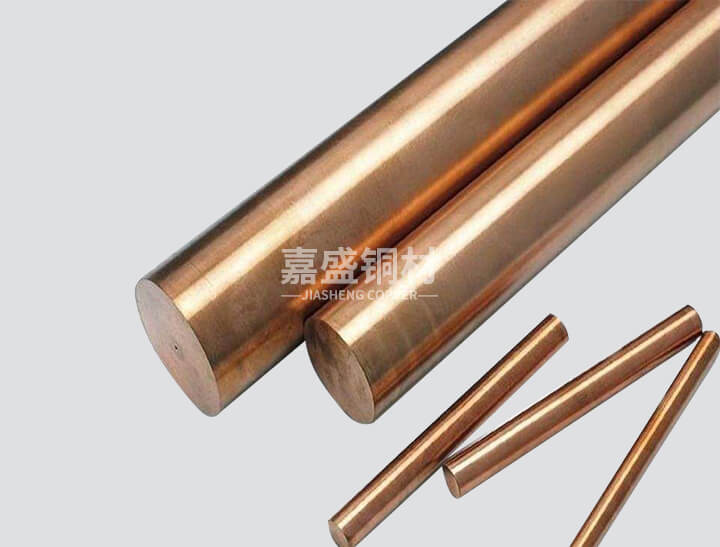

Available shapes & sizes of C17500 Beryllium Copper

Shape: Round, Rod Bar, Flat, Hexagon,Plate Sheet, Half-round or Customized

Sizes: Standard or Customized

Standard: GB/T,JIS,ASTM, ISO, DIN, BS, NF etc.

Hardness: 1/16 hard,1/8 hard,3/8 hard,1/4 hard,1/2hard,full hard.

Packaging Details:wooden case or woven bag

Processing Service:Bending, Welding, Decoiling, Cutting, Punching

Deliver time: According to order's quantity.

Chemical Composition (%) of C17500 Beryllium Copper

Cu* Ni Be Pb Co

Remainder 0.3 max. 0.4~0.7 0.2-0.6 1.4~2.7

Mechanical Properties of C17500 Beryllium Copper

Cold working performance: C17500 beryllium copper has excellent cold working properties. It can undergo cold working processes such as stamping, stretching, and bending, and is unlikely to suffer from cracking, breaking, or deformation defects.

Heat processing performance: The heat processing performance of this alloy is also very good. It can undergo heat processing techniques such as forging, hot rolling, and hot extrusion within the temperature range of 300℃ to 800℃.

Heat treatment performance: Through heat treatment, the mechanical properties and corrosion resistance of the material can be improved.

Physical Properties of C17500 Beryllium Copper

Density: 8.36 - 8.44 g/cm³

Heat conductivity: 128 - 150 W/(m·K)

Electrical conductivity: 45 - 52% IACS

Hardness: 210 - 280 HV

Tensile strength: 900 - 1200 MPa

Yield strength: 600 - 1050 MPa

Extension rate: ≥ 5%

Elastic modulus: 138 GPa

Softening temperature: Up to 520℃

Other properties: C17500 beryllium copper also has excellent corrosion resistance, polishing properties, anti-adhesion properties, machinability, and extremely excellent welding properties.

Typical Uses for C17500 Beryllium Copper

Electrical and electronic industry (the largest application field):

High current density connectors and connectors (requiring low resistance and low temperature rise).

Contacts of relays and switches, switch components, springs, diaphragms.

Welding electrodes and their accessories (holders, bases): Utilizing their high conductivity, heat conductivity and resistance to high-temperature softening.

Battery components, semiconductor lead frames (requiring high conductivity).

Mold industry:

Core components, inserts, and ejector pins of plastic injection molding molds (especially in areas requiring rapid cooling). Their high thermal conductivity accelerates the cooling and molding of plastics, shortening the production cycle.

Blow molding mold components.

Some components of die casting molds (less used in C17200 applications).

Welder equipment:

Resistance welding electrodes (spot welding, roll welding, projection welding), electrode arms, welding torch.

Precision instruments and meters:

Require sensitive components and spring sheets that are non-magnetic, highly elastic and resistant to fatigue.

Petroleum and natural gas tools:

Non-magnetic drill collar internal parts, sensor housing (using non-magnetic material).

Others:

Bearings, bushings (require wear resistance).

Springs (require good electrical conductivity and resistance to stress relaxation).

Provides a wide range of high performance services across multiple industries and technologies

-

FAQ’s

For quick answers to our customers FAQ’s. -

Quotations

Get the latest and most favorable quotations -

Other informations

Product specifications, catalogues, tests, samples, performance, etc