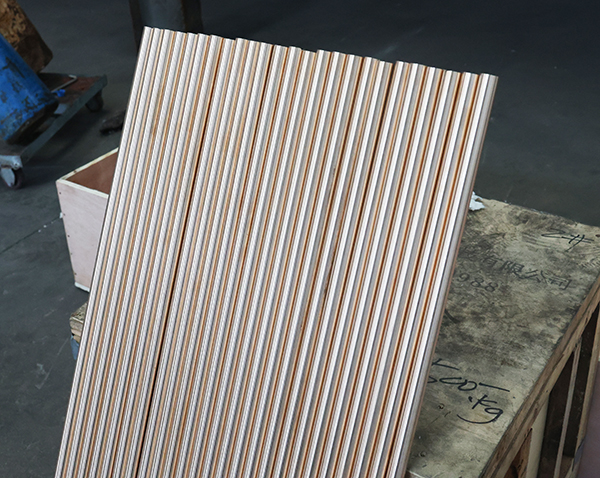

High temperature resistant mold C17300 beryllium cobalt copper rod

Softening temperature: 750

Diameter: 1.0mm - 220mm

Length: 2.0mm - 6000mm

Shape: Round bar, square bar, hexagonal bar

Tolerance: 0.02mm

Surface: Smooth, no sand holes

The C17300 beryllium copper rods used for high-temperature molds have a smooth surface, good straightness, are easy to machine, and are suitable for professional cutting.Alloy copper rod, easy to machine, durable and with good straightness.

Specification of High temperature resistant mold C17300 beryllium

Conductivity: 99.97

Custom processing: Yes

Softening temperature: 750

Diameter: 1.0mm - 220mm

Length: 2.0mm - 6000mm

Shape: Round bar, square bar, hexagonal bar

Tolerance: 0.02mm

Surface: Smooth, no sand holes

Packaging: Fleece film, pearl cotton, wooden tray, wooden box

C17300 beryllium copper Chemical composition:

Cu:≥99.50

Ni+Co:≤0.6(Ni+Co≮0.20)

Be:1.8~2.0

Pb:0.20~0.60‘

C17300 beryllium copper standard:ASTMB196-1990

High-temperature stability

C17300 beryllium copper can maintain excellent mechanical properties at high temperatures and is suitable for high-temperature and high-load conditions. For example, in automotive components, its high-temperature resistance can extend the service life of the equipment.

Correlation between composition and performance

This alloy contains approximately 1%-2% beryllium (with an atomic percentage of 9.0122%). The addition of beryllium significantly improves its heat resistance. During high-temperature operations (such as melting and welding), the alloy forms beryllium oxide (BeO), but its structural stability is still superior to that of ordinary copper alloys.

Beryllium-cobalt-copper is widely used in the manufacture of inserts and cores for injection molds or steel molds. When used as inserts in plastic molds, it can effectively reduce the temperature in the heat concentration area, simplifying or eliminating the design of cooling channels.

Application of C17300 Beryllium-Cobalt Copper Rod in Mold Manufacturing:

The beryllium-cobalt copper rod C17300 is widely used in manufacturing inserts and cores for injection molds or steel molds. When the C17300 beryllium-cobalt copper rod is used as an insert in plastic molds, it can effectively reduce the temperature in the heat concentration area and simplify or eliminate the design of cooling channels. The extremely excellent thermal conductivity of beryllium-cobalt copper is about 3 to 4 times better than that of mold steel. This characteristic ensures that plastic products are cooled quickly and uniformly, reducing deformation of the products, unclear details and similar defects. In most cases, it can significantly shorten the production cycle of the products. Therefore, the beryllium-cobalt copper C17300 beryllium-cobalt copper rod can be widely applied in molds, cores, inserts that require rapid and uniform cooling, especially for high thermal conductivity, corrosion resistance and good polishing requirements.

Blow molding molds: Clamping part, spring ring and handle parts inserts.

Injection molds: Molds, cores, corner inserts of TV shells, nozzles and junction chambers of heat flow systems.

Leave a Messages