C17300 beryllium copper rod high conductivity component beryllium copper alloy

Hardness: 135 ± 35HV

Copper content: Cu ~ 90.0%

Conductivity: ≥ 18% IACS

Custom processing: Yes

Softening temperature: 600℃

Type: Copper rod material

Material: C17300

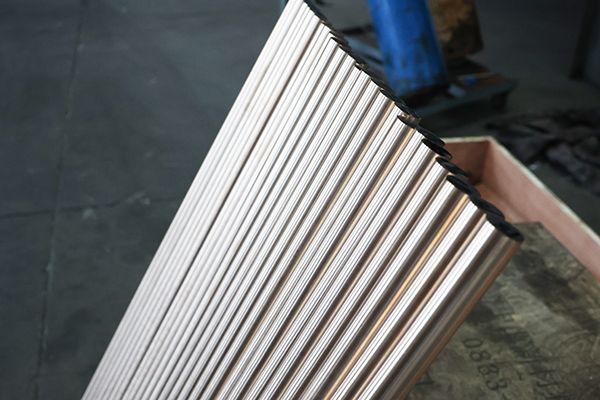

C17300 beryllium copper rod is a high-performance alloy material with copper as the base (remaining amount), containing 1.8% - 2.0% beryllium and trace amounts of cobalt and nickel. The shape of C17300 beryllium copper rod is usually round or square rods, with a smooth surface and high dimensional accuracy. It is suitable for precision processing and is widely used in mold inserts, electronic connectors, and hot runner systems, etc.

Specifications of C17300 beryllium copper rod

Hardness: 135 ± 35HV

Copper content: Cu ~ 90.0%

Conductivity: ≥ 18% IACS

Custom processing: Yes

Softening temperature: 600℃

Type: Copper rod material

Material: C17300 alloy

The electrical conductivity of C17300 beryllium copper rod

In terms of electrical conductivity, C17300 beryllium copper maintains 60% of the electrical conductivity of copper (approximately 22% IACS), which is much higher than that of other high-strength alloys.

The high electrical conductivity makes C17300 beryllium copper suitable for scenarios with strict requirements for heat and electricity management, such as electronic components, heat sinks, and efficient electrodes. The conductivity of 22-28% IACS is superior to stainless steel and close to pure copper. Its conductivity is much higher than that of other high-strength alloys, effectively preventing overheating during operation.

High-quality copper raw materials meet the copper content standards and possess excellent electrical conductivity, thermal conductivity and corrosion resistance, with a bright color.

Excellent high and low temperature performance

Can maintain its mechanical and physical properties at high and low temperatures

Good straightness of the material

High strength, hardness, elasticity, wear resistance, fatigue limit and heat resistance.

Applications of C17300 beryllium copper rod

Electronic and Electrical Industry

High-precision contacts and spring clips: High conductivity and fatigue resistance ensure long-term reliable contact.

Vibration plates and diaphragms: Low elastic lag makes them suitable for high-frequency vibration applications.

Leave a Messages