C17300 beryllium copper Cube2Pb--C17300 (CDA 173)

C17300 beryllium copper (ASTM B196-1990) is a precipitation hardening beryllium copper alloy. Its composition is similar to that of AISI C17200, and it exhibits excellent cold working properties, good hot working properties, and outstanding cutting processing capabilities.

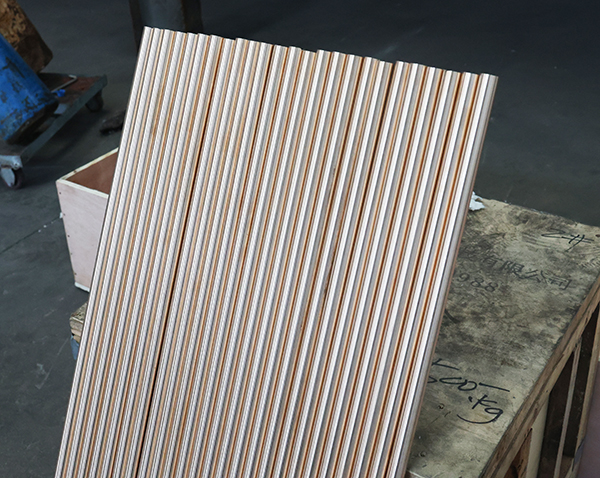

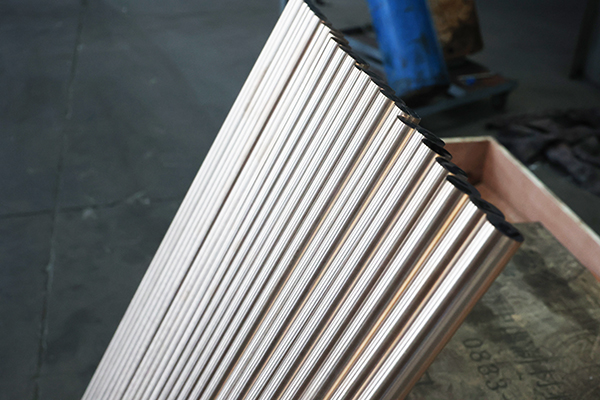

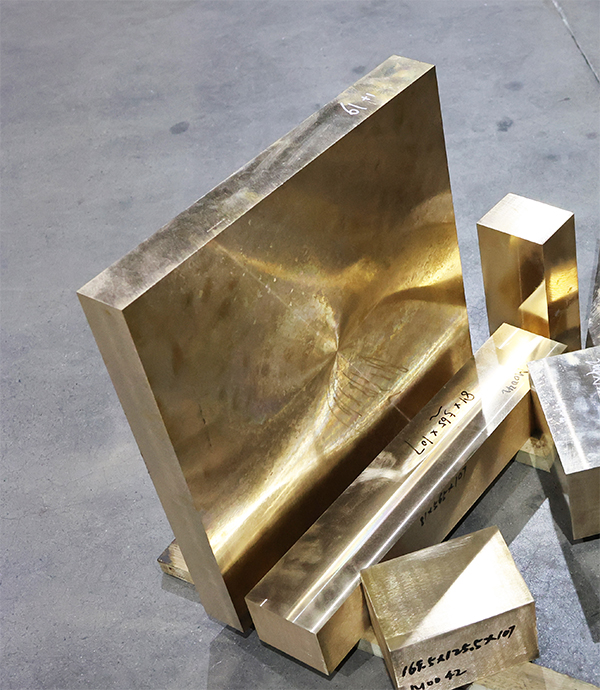

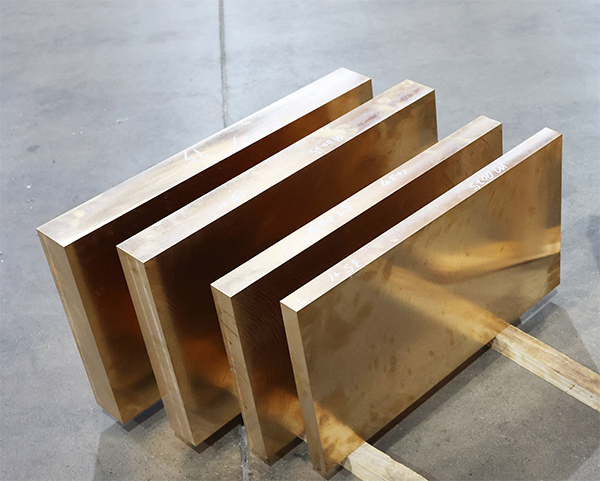

Available shapes & sizes

Shape: Round, Square, Flat, Hexagon, Oval, Half-round or Customized

Sizes: Standard or Customized

Standard: GB/T,JIS,ASTM, ISO, DIN, BS, NF etc.

Hardness: 1/16 hard,1/8 hard,3/8 hard,1/4 hard,1/2hard,full hard.

Package: Plastic film + Wooden case or as per customer requirement

Surface: Polished,bright,oiled,hair line,brush,mirror,or as required

Deliver time: According to order's quantity.

Chemical Composition (%)

Cu* | Ni + Co | Ni + Co + Fe | Be | Pb | Co | Others |

Remainder | 0.20 min. | 0.6 max. | 1.80 – 2.00 | 0.2-0.6 | 0.2-0.6 | 0.5max. |

Mechanical Properties of C17300 beryllium copper

Through solid solution + aging heat treatment, the mechanical properties of C17300 beryllium copper have been significantly improved:

Tensile strength: Approximately 500 - 700 MPa in the annealed state, and up to 1100 - 1400 MPa after aging treatment.

Yield strength: Approximately 200 - 400 MPa in the annealed state, and increases to 900 - 1200 MPa after aging.

Strain rate: In the annealed state, it is 10% to 25%, and after aging, it drops to 3% to 10% (still superior to most high-strength alloys).

Hardness: The aged Rockwell hardness (HRC) can reach 35 to 42. The surface can be further strengthened for wear resistance through coating.

Elastic modulus: Approximately 128 GPa. High rigidity makes it suitable for springs and elastic components.

Physical Properties of C17300 beryllium copper

Density: Approximately 8.25 g/cm³, lying between pure copper and steel, making it suitable for lightweight and precision components.

Melting point: Approximately 865°C to 980°C. It can maintain structural stability even at high temperatures.

Conductivity: The conductivity is approximately 22% - 28% of pure copper (according to IACS standards), suitable for high current density applications.

Thermal conductivity: The thermal conductivity reaches 100 W/(m·K), suitable for applications requiring efficient heat dissipation.

Coefficient of thermal expansion: 17.5×10⁻⁶/℃ (20°C - 300°C), low expansion property is suitable for precision instruments.

Magnetic property: Non-magnetic. Suitable for electronic shielding or environments with magnetic sensitivity.

Typical Uses for C17300 Beryllium Copper

Electrical and Electronic: Connector contacts, relay springs, chip test probes (utilizing high conductivity and elasticity).

Aerospace: Precision gears for aircraft, elastic components of navigation systems, hinges for satellite antennas.

Mold manufacturing: Plastic injection mold inserts (high thermal conductivity reduces cooling time).

Military industry and energy: Nuclear reactor control rod drive mechanism, pressure-resistant components for deep-sea probes.

Mechanical Industry: Precision gears, bearings, high-strength fasteners.

Petrochemicals: Explosion-proof tools, valve components.

Consumer goods: High-end audio diaphragms, golf club heads.

Provides a wide range of high performance services across multiple industries and technologies

-

FAQ’s

For quick answers to our customers FAQ’s. -

Quotations

Get the latest and most favorable quotations -

Other informations

Product specifications, catalogues, tests, samples, performance, etc