Will chromium zirconium copper corrode rapidly in a humid environment?

Summary of the conclusion:

Chromium-zirconium-copper (CuCrZr) does not "rapidly corrode" in general humid environments. Its corrosion resistance is superior to that of ordinary pure copper. However, when exposed to high humidity, salt-containing, or acidic atmospheres for a long time, it will still undergo a certain degree of corrosion, and alternating between dry and wet conditions will accelerate the corrosion process. Specifically:

In general humid environment: A dense protective film (such as Cu₂O) can form on the surface, and the corrosion rate is relatively low, similar to or slightly better than that of pure copper.

In high humidity/salt fog/acidic atmosphere: Corrosion accelerates, especially in the presence of chlorine, sulfur and other contaminated media, where obvious pitting corrosion or uniform corrosion occurs.

In dry-wet alternation: It is more destructive than continuous humidity. The protective film of corrosion products repeatedly dissolves and regenerates, reducing its protective effect, and the corrosion rate increases.

1. Corrosion behavior in general humid environments

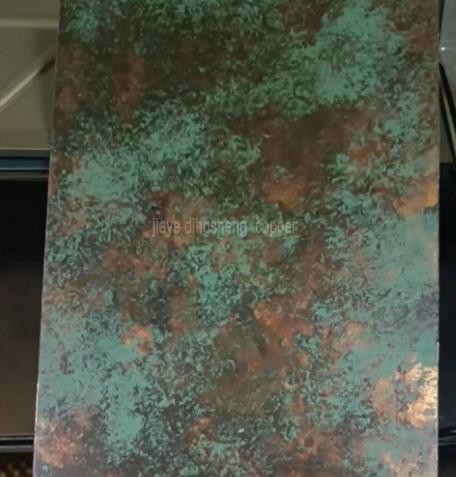

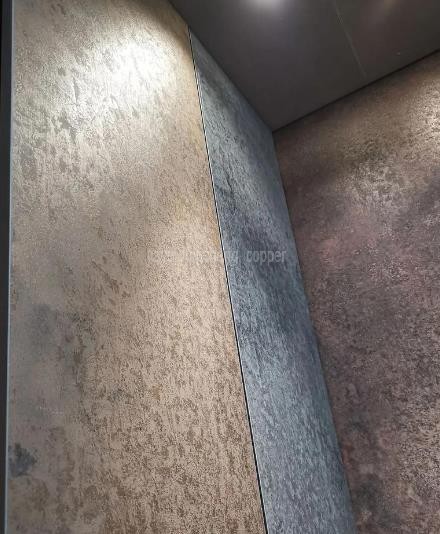

In the atmosphere or in general humid conditions, chromium-zirconium copper will form insoluble in water and tightly bonded with the substrate copper sulfate (green copper) or copper carbonate films on the surface, which can prevent the corrosion from further developing and thus has good corrosion resistance.

The addition of chromium and zirconium can enhance the alloy's oxidation resistance and passivation ability. It has good chemical stability in most media and exhibits better corrosion resistance than pure copper.

2. Corrosion under high humidity/salt spray/acidic conditions

Under salt spray or contaminated media containing chlorine, sulfur, etc., chloride ions can penetrate the surface oxide layer and cause electrochemical corrosion, resulting in pitting corrosion or a significant increase in uniform corrosion rate.

The results of salt spray tests show that copper alloys exhibit obvious corrosion within a few hours to several tens of hours under accelerated salt spray conditions (NSS/ASS/CASS), indicating that extremely humid/salt-containing environments have a strong erosive effect on chrome-zirconium copper.

Laboratory accelerated corrosion (such as immersion in 3.5% NaCl solution for 168 hours) also indicates that the corrosion rate of chrome-zirconium copper remains basically constant over time, and the protective effect of the product film is limited.

3. The Impact of Alternating Dry and Wet Conditions

Alternating dry and wet conditions are one of the most destructive factors in atmospheric corrosion. Repeated exposure to moisture and drying leads to the continuous dissolution and regeneration of the corrosion product layer, resulting in a decrease in protective properties and a higher corrosion rate compared to continuous wet conditions.

Under dry-wet cycling conditions, the corrosion products of copper and copper alloys mainly consist of Cu₂O, CuO, and basic copper sulfate. The weight loss due to corrosion increases linearly over time, indicating that the corrosion process is ongoing.

4. Corrosion Rate Data Reference

Although the specific annual average corrosion rate of chromium-zirconium copper in general humid environments has not been found, the corrosion rates of copper and copper alloys in typical atmospheric environments can be referred to: usually 0.1–1 µm/year (rural/urban), and up to 1–10 µm/year in industrial areas/oceans.

Due to alloying, the corrosion rate of chromium-zirconium copper is usually lower than that of pure copper, but it will significantly increase under harsh conditions (such as salt fog, industrial pollution).

Protection recommendations

General environment: Chromium-zirconium-copper can be used for a long time without special protection.

High humidity/salt spray/acidic environment: It is recommended to use surface coatings, electroplating or regular maintenance to extend the service life.

Dry-wet alternating/industrial polluted environment: Surface protection should be strengthened or more corrosion-resistant materials such as stainless steel or nickel-based alloys should be selected.

Conclusion: Chromium-zirconium-copper does not corrode rapidly under normal humid conditions. However, in high humidity, salt spray, acidic, or alternating dry-wet environments, the corrosion will accelerate, and appropriate protective measures must be taken.

.jpg)