How to handle beryllium bronze in a timely manner

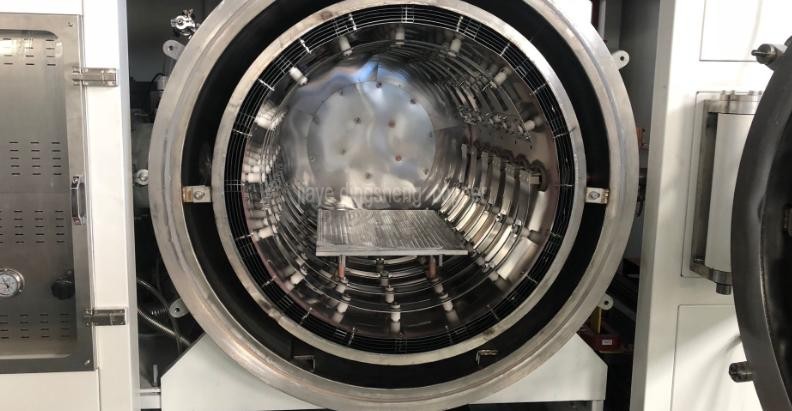

What is a beryllium copper vacuum aging furnace used for?

The beryllium copper vacuum aging furnace is a specialized equipment for material heat treatment, mainly used to eliminate internal stress in metal materials and improve their properties. It places the material in a vacuum environment and heats it for a certain period of time to allow the internal structure of the material to undergo ideal changes. This treatment method avoids oxidation and ensures a smooth surface on the material, making it an indispensable process equipment in fields such as aerospace and precision instruments.

Working principle of the beryllium copper vacuum aging furnace

l Vacuum environment: First, evacuate the air to prevent oxidation of the material

l Precise temperature control: Resistance wire heating, temperature controlled to ±5

l Aging treatment: Maintain a constant temperature for several hours to allow the internal structure of the material to change uniformly

l Slow cooling process: After treatment, slowly cool down to avoid generating new stress

Basic principle of beryllium copper aging treatment

beryllium copper (such as C17200) is a copper alloy that can be strengthened through heat treatment. The core is to enhance hardness and strength by precipitating beryllium metal intermetallic compounds (such as BeCu phase) during the aging process. The aging treatment is divided into two steps:

l 1. Solution treatment: Heat the material to 780-820℃ (according to ASTM B196 standard), hold for 1-2 hours to allow the beryllium element to dissolve fully, then quench it in water to room temperature to obtain an over-saturated solid solution.

l 2. Artificial aging: Hold at 260-320℃ for 2-4 hours (adjust according to the grade), promoting the uniform distribution of the precipitated phase. For example, the typical aging process of C17200 is 315℃×3 hours, with a hardness of HRC38-42 (data source: "ASM Handbook").

Influence of aging process parameters on performance

l 1. Temperature control:

- Below 260℃ leads to too slow precipitation speed and insufficient hardness;

- Above 320℃ may cause coarse precipitated phases and decreased strength. Experiments show that 300℃ aging can achieve an tensile strength of 1200MPa (data source: "Copper Alloy Materials Science").

l 2. Time optimization:

- Insufficient aging time (<2 hours) leads to incomplete precipitation;

- Excessive aging time (>5 hours) may cause grain boundary brittleness.

Analysis of beryllium copper heat treatment process

Solution treatment process

The solution treatment of beryllium copper involves precise control of the heating temperature, usually between 760-780℃, to avoid coarse grain formation. Solution treatment is a crucial step, requiring uniform furnace temperature control and following specific process specifications to ensure the ductility and strength of the material.

Grade | Part category | Heating temperature/℃ | Holding time/min | Cooling medium

QBe2 | General | 780±10 | t | Water (≤35℃)

QBe1.9 | Special | 780±5 | t | Water (≤25℃)

The calculation of holding time follows the formula: t = A×B + D, where A is the holding time coefficient, B is the effective thickness, and D is the holding time constant. The coefficients for elastic parts are different, and the coefficients for special elastic parts are also different. Loading into the furnace should be done when the furnace temperature reaches the set value, and the holding time is calculated from the time when the instrument shows the temperature reaches the set value. For quenching, generally clean water is used, and for preventing deformation, complex-shaped parts can use oil as the quenching medium.

During the solution heating treatment process, surface oxidation should be prevented to extend service life. beryllium copper forms an oxide film on the surface in air or oxidizing atmosphere, so it is best to heat in a vacuum furnace or in a reducing atmosphere to avoid oxidation.

Aging treatment process

The aging treatment temperature of beryllium bronze depends on its beryllium content. It usually includes soft aging and hard aging processes. For alloys with different beryllium contents, there are specific temperature and holding time ranges. For example, when the beryllium content is greater than 1.7%, the optimal aging temperature is 300-330℃, and the holding time is 1-3 hours. For high conductivity electrode alloys, due to the increase in melting point, the optimal aging temperature is 450-480℃. In recent years, two-stage and multi-stage aging processes have developed, which improve performance and reduce deformation.

Stress relief treatment

Stress relief annealing eliminates residual stress by heating at a temperature range of 150-200°C, thereby improving the shape and size stability of the material. After metal cutting processing or cold forming, to ensure the shape and size accuracy of the parts, stress relief annealing can be adopted. The annealing temperature is controlled within 150-200°C, and the holding time is 1-1.5 hours. Using a protective atmosphere for aging treatment not only reduces oxidation but also promotes heat transfer. After this treatment, the density of the material will increase, and the size will contract by approximately 0.2% along the line.

During the treatment process, the use of a protective atmosphere can reduce oxidation and ensure the uniformity of the treatment. The cooling method also needs to be noted to prevent deformation. It is recommended to use fixtures for fixation to reduce deformation and distortion after the treatment.

# Tags:

-

How to handle beryllium bronze in a timely manner