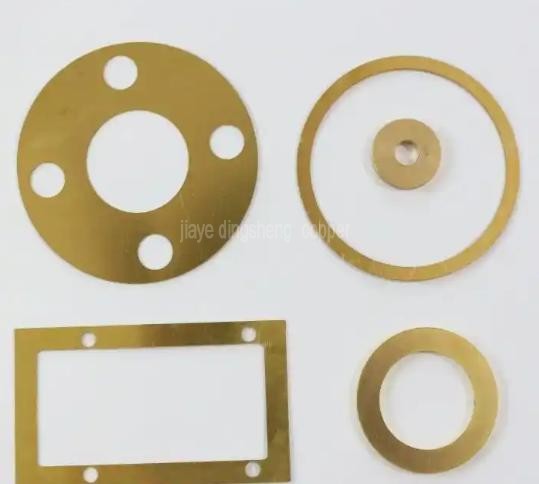

Will beryllium bronze deform if it becomes thinner?

Yes, the thin sheets of beryllium bronze will deform due to factors such as component content and process parameters.

Physical principles

Beryllium bronze is a material with high strength and high electrical conductivity, with its main components being copper and beryllium. During the cold processing, the pressure applied during the manufacturing of the thin sheets will change the internal structure of the material, causing common deformation problems such as planar deformation, bending, warping, etc. This may be due to the inhomogeneity of the beryllium bronze crystal structure, so the manufacturing process largely determines the quality of the thin sheets. Process parameters.

The deformation problem of the beryllium bronze sheet is also related to the process parameters. During the processing, factors such as eccentricity, the roundness of the workpiece cutting edge, and the cutting angle will all affect the degree of deformation of the beryllium bronze sheet. Once these factors deviate, it is very likely to cause deformation of the sheet or exceed the tolerance range.

Solution

To avoid or reduce the deformation of the beryllium bronze sheet, it is necessary to strengthen the manufacturing process and control the process parameters to ensure the quality of each process. For example:

Control the composition content of the material to meet the manufacturing requirements.

2. Select appropriate process parameters, maintain uniform heating during the process, reduce the roller diameter and track width of the press roller, and control the error.

3. Use appropriate process methods, such as cooling and heat treatment, to control its internal structure and mechanical properties.

4. For sheets with deformation exceeding the tolerance range, mechanical or heat treatment methods can be used for repair.

How to control the deformation of the parts?

The key lies in the selection and application of alloys and tempering, as well as the conditions for aging hardening and stamping adjustments. Through reasonable alloy ratios and tempering treatments, the partial distortion can be effectively controlled. Moreover, adjustments during the stamping or processing stages are also indispensable steps.

In conclusion, the thin sheets of beryllium bronze will deform due to factors such as component content and process parameters. During the manufacturing process, it is necessary to strictly control the process parameters to ensure product quality.

# Tags:

-

Will beryllium bronze deform if it becomes thinner