Detailed Classification of Phosphor Bronze Grades

Phosphor bronze currently has five main grades, namely C54400, C52100, C53400, C83600 and C83800.

Overview of Phosphor Bronze Grades

Phosphor bronze currently has five main grades, namely C54400, C52100, C53400, C83600 and C83800.

Overview of Phosphor Bronze Grades

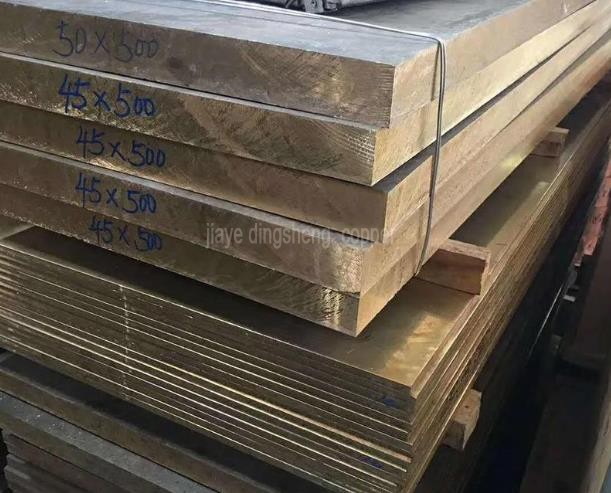

Phosphor bronze is a copper alloy made by adding certain amounts of phosphorus, tin and zinc and other elements to copper.Phosphor bronze is a copper alloy made by adding certain amounts of phosphorus, tin and zinc and other elements to copper. Due to its excellent corrosion resistance, wear resistance and mechanical strength, it has been widely used in industrial production and daily life. Due to its excellent corrosion resistance, wear resistance and mechanical strength, it has been widely used in industrial production and daily life. The grades of phosphor bronze materials are usually composed of numbers and letters, where the numbers represent the percentage of phosphorus content and the letters represent other alloy elements.

II. The grades of phosphor bronze materials are usually composed of numbers and letters, where the numbers represent the percentage of phosphorus content and the letters represent other alloy elements.

Classification of Phosphor Bronze Grades

At present, the grades of phosphor bronze materials are mainly divided into the following five types: C54400

At present, the grades of phosphor bronze materials are mainly divided into the following five types: C54400

C54400 is a copper alloy containing 4% to 5.C54400 is a copper alloy containing 4% to 5.5% phosphorus, along with 0.2% tin and 0.5% phosphorus, along with 0.05% zinc.2% tin and 0.05% zinc. The main advantage of this material is its excellent corrosion resistance and mechanical strength, making it suitable for manufacturing parts that operate under high-load and high-corrosion conditions. 2. C52100

The main advantage of this material is its excellent corrosion resistance and mechanical strength, making it suitable for manufacturing parts that operate under high-load and high-corrosion conditions. 2. C52100

C52100 is a copper alloy containing 6% to 8% phosphorus, along with 0.05% tin and a small amount of zinc and copper. The main features of this material are high hardness and good wear resistance, making it suitable for manufacturing bearings, couplings, etc. that undergo high-pressure and high-speed friction. 3. C53400

C53400 is a copper alloy containing 7% to 9% phosphorus, along with 0.4% tin and a small amount of zinc and copper. The main characteristics of this material are its excellent wear resistance and corrosion resistance, making it suitable for manufacturing parts such as mining machinery and textile machinery. 4. C83600

C83600 is a copper alloy containing 4% to 6% phosphorus, along with 5% to 7% zinc and small amounts of elements such as aluminum and tin. The main features of this material are its low phosphorus content, excellent mechanical properties, strong corrosion resistance, and suitability for manufacturing pipes, pump housings, etc. 5. C83800

C83800 is a copper alloy containing 14% to 16% phosphorus, with a small amount of tin and zinc and other elements. The main characteristics of this material are extremely high hardness, good wear resistance, high strength, and low magnetic permeability. It is suitable for manufacturing high-performance bearings, gears, etc.

III. Application fields of phosphor bronze

Phosphor bronze materials have the advantages of wear resistance, corrosion resistance, and high mechanical strength. Therefore, they have a wide range of applications, mainly including the following fields:

1. Mechanical manufacturing: Phosphor bronze materials can be used to manufacture mechanical parts such as bearings, gears, and couplings.

2. Shipbuilding: Phosphor bronze materials can be used to manufacture ship accessories, propeller shafts, etc.

3. Energy field: Phosphor bronze materials can be used to manufacture hydraulic components, pipes, valves, etc.

4. Mining machinery: Phosphor bronze materials can be used to manufacture bearing, gear, and sleeve parts for mining machinery.

In summary, phosphor bronze materials have good mechanical properties and corrosion resistance, and are a commonly used copper alloy material. The selection of its grade should be comprehensively considered in combination with the usage conditions and requirements.

# Tags:

-

classification of phosphor bronze