UNS C17510 (Alloy 3):CuNi2Be

The processing performance of C17510 beryllium bronze is suitable for various processing methods, including forging, stretching, stamping, and milling, etc. Due to its excellent weldability, multiple processing techniques can be adopted during the manufacturing process to meet specific design requirements.

In terms of application advantages, the C17510 beryllium bronze exhibits excellent electrical and thermal conductivity, which has enabled it to be widely used in the electrical and electronic industries. Its high strength and corrosion resistance also make it the preferred material for manufacturing aerospace, military equipment, and marine engineering components. Moreover, when used in certain moving components, its wear resistance also provides a reliable guarantee for the long lifespan of the equipment.

Specification of C17510 copper alloy

UNS/CDA: UNS. C17510, CDA 1751

ASTM: B441

MIL: SAEJ 461,463

RWMA: Class 3

DIN: 2.0850, CW110C

Chemical Composition of C17510 beryllium copper

Be: 0.20-0.60%

Ni: 1.40-2.20%

Cu: Balance

Note:

Cu+Be+Co+Ni+Fe: 99.50% Min.

Physical Properties of C17510 beryllium copper

Density (g/cm3) | 0.317Ib/in3 at 68F |

Specific Gravity | 8.83g/cm3 |

Melting Point(Liquidus) | 1955F |

Melting Point(Solidus) | 1885F |

Electrical Resistivity | 22.8 ohms/cmil/ft@68F |

Electrical Conductivity | 48%IACS@68F(heat-treated) |

Chemical Composition:CuNi2Be

Material:Alloy

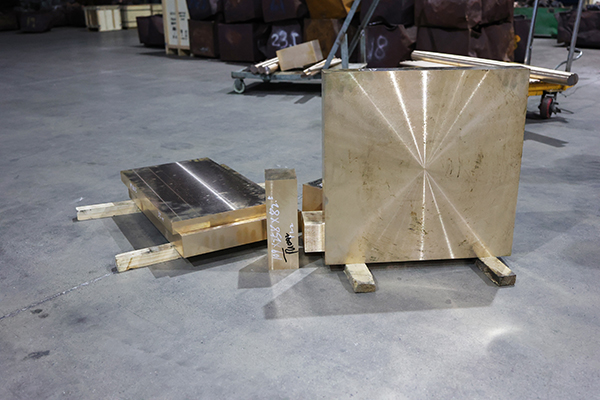

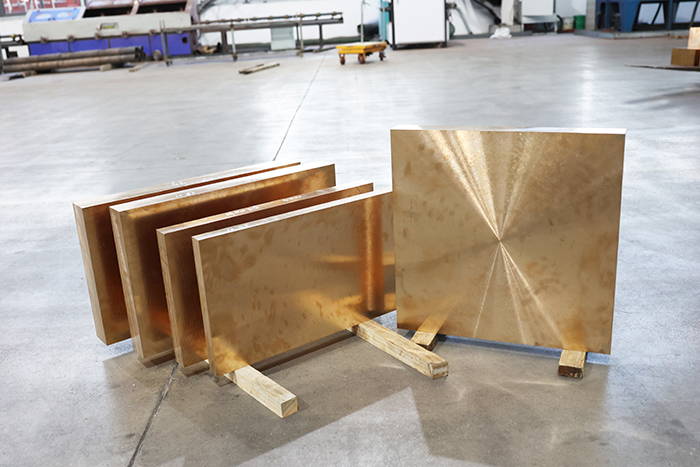

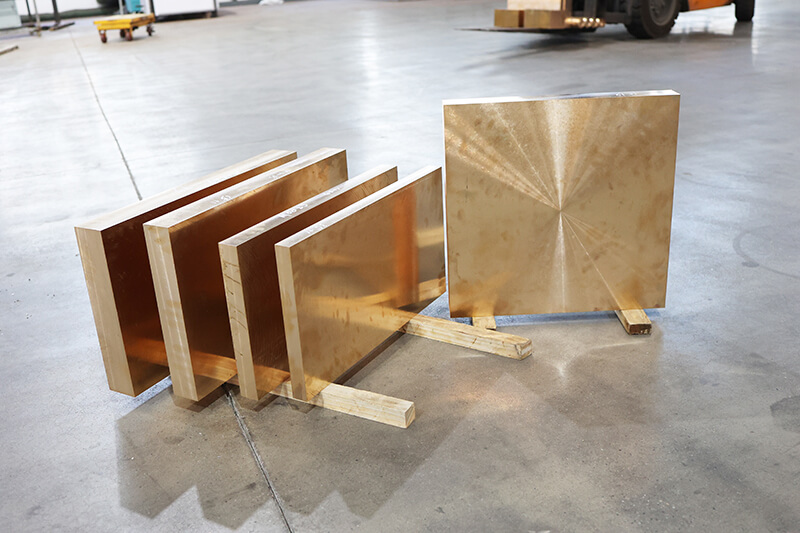

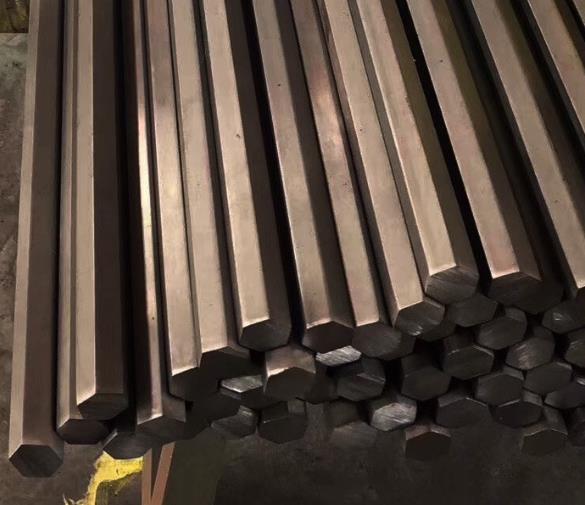

Shape:Bar

Standard:ASTM

Color:Bronze, Golden

Type:Copper

Surface:Polished,Mill,Brush,Bright,Sand Blast,etc

Processing Service:Cutting,Bending,Decoiling,Welding,Punching,etc

Free Cutting

Application

Electrical Industry

Electrical Switch and Relay Blades, Fuse Clips, Switch Parts, Relay parts, Connectors, Spring Connectors, Contact Bridges, Belleville Washers, Navigational Instruments, Clips

Fasteners

Washers, Fasteners, Lock Washers, Ret

Provides a wide range of high performance services across multiple industries and technologies

-

FAQ’s

For quick answers to our customers FAQ’s. -

Quotations

Get the latest and most favorable quotations -

Other informations

Product specifications, catalogues, tests, samples, performance, etc