Why should the mold use beryllium copper as the material?

Characteristics of beryllium copper

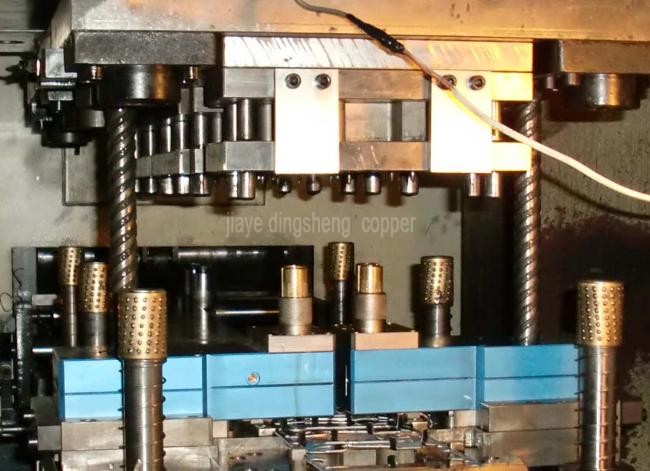

Beryllium copper is an alloy material with high strength, high hardness, high thermal conductivity, oxidation resistance and corrosion resistance. It has excellent casting properties and machinability. In mold manufacturing, it can be processed through casting, forging, fine processing and heat treatment, resulting in precise mold products.

The wear resistance and fatigue resistance of beryllium copper are excellent. Under high load, high speed and high temperature conditions, the mold material will be greatly affected. Therefore, it needs to have excellent wear resistance and corrosion resistance, and should not deform or develop fatigue cracks over a long period of use. Beryllium copper precisely possesses these characteristics.

Application fields of beryllium copper in mold manufacturing

Beryllium copper is often used to manufacture injection molds, die-casting molds, stretching molds, extrusion molds, etc. Due to the excellent wear resistance, corrosion resistance, high hardness and high thermal conductivity of beryllium copper, it is suitable for producing high-precision and high-demand products, such as automotive parts, aerospace components and electronic product housings.

Processing technology of beryllium copper alloy materials

The unique material properties of beryllium copper require special processing techniques to achieve high precision and quality processing. For complex mold shapes, numerical control processing or pulse electric processing technologies are usually adopted. These advanced processing equipment can reduce processing errors, lower production costs, and increase production efficiency.

In addition, in mold manufacturing, the heat treatment of beryllium copper is also very important. With appropriate heat treatment, the hardness and strength of the material can be improved, while maintaining good toughness.

In conclusion, beryllium copper has an irreplaceable advantage in mold manufacturing. Choosing beryllium copper as the mold material can achieve higher precision requirements, reduce the number of mechanical processing steps, increase mold life, and lower production costs.

Why use beryllium copper for mold cores

The role of mold cores

Mold cores are parts that support and position in the mold. They are usually used to manufacture some complex internal geometric shapes in the mold, for the positioning and processing of parts.

Why use beryllium copper

1. Good wear resistance

Beryllium copper has excellent wear resistance, which is one of the main reasons why beryllium copper becomes the material for mold cores. During the continuous friction and force application of the mold, the beryllium copper core will not deform or wear, ensuring the accuracy and lifespan of the mold.

2. Good heat conductivity

Beryllium copper has excellent heat conductivity, with its heat conduction speed being about 30% faster than steel. Therefore, it is very suitable for mold cores that require high-temperature processing.

3. Good oxidation resistance

Beryllium copper has excellent corrosion resistance and oxidation resistance, which can prevent damage to the mold core caused by oxidation and corrosion, thereby extending the lifespan of the mold.

4. Easy to process

Beryllium copper is easier to process than other metal materials, and can be easily cut, drilled, and threaded processed, making beryllium copper the preferred material for mold cores.

Application of beryllium copper in mold manufacturing

Beryllium copper has many applications in mold manufacturing, such as injection molds, die-casting molds, stretching molds, etc. Due to its excellent thermal conductivity, wear resistance, oxidation resistance, etc., it can help molds withstand special processing conditions such as high pressure, high temperature, and high speed, ensuring mold accuracy and lifespan.

In conclusion, beryllium copper, as a mold core material, plays an important role in mold manufacturing. It has many advantages such as wear resistance, heat conductivity, oxidation resistance, and ease of processing, which can help molds withstand special processing conditions and ensure mold accuracy and lifespan.

# Tags:

-

the mold use beryllium copper