The performance characteristics of beryllium bronze

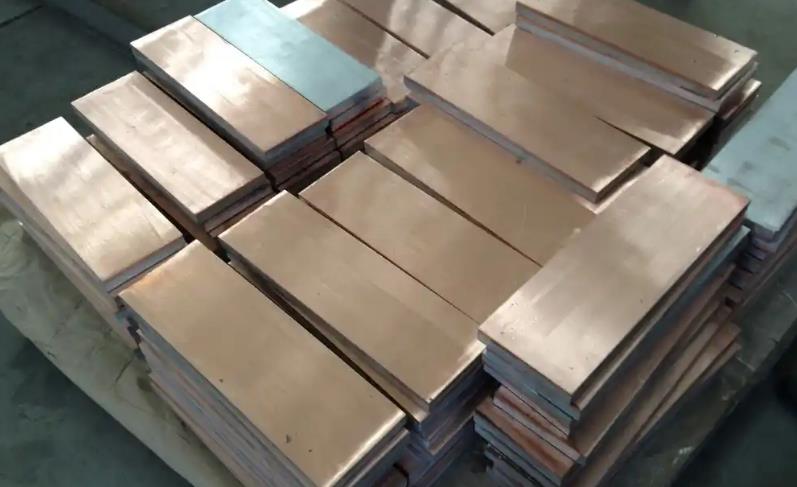

Basic Overview of Beryllium Bronze

Beryllium bronze is a copper alloy with beryllium as the main alloying element. The beryllium content is typically controlled within the range of 1.7% to 2.5%. This unique alloy design enables beryllium to perfectly dissolve into copper, forming a solid solution, and the solubility varies significantly with temperature. What is particularly noteworthy is that beryllium bronze is the only copper alloy that can significantly enhance its performance through the solid solution aging strengthening process. This characteristic makes it suitable for numerous high-end application scenarios.

Performance Characteristics

Mechanical Properties

After quenching and artificial aging treatment, the tensile strength of beryllium bronze can soar to 1250-1500 MPa, and its hardness reaches 350-400 HBW. This data far exceeds that of other copper alloys, and even rivals that of high-strength alloy steels. This indicates that beryllium bronze can withstand extremely high external loads while maintaining the integrity and stability of the structure.

High Elasticity and Fatigue Resistance

Beryllium bronze also possesses extremely high elastic limit and fatigue strength. Even when subjected to alternating stresses over a long period, it can maintain excellent performance stability and is unlikely to fracture or fail. It is an ideal material for manufacturing precision instrument springs and elastic components.

Wear-resistant and corrosion-resistant, conductive and heat-conductive

Its outstanding wear resistance and corrosion resistance enable beryllium bronze to maintain excellent performance even in harsh environments. Additionally, its excellent conductivity and heat conductivity make it have broad application prospects in the fields of electricity and electronics.

Non-magnetic, cold-resistant, safe and reliable

Beryllium bronze also possesses the characteristics of being non-magnetic, cold-resistant, and not generating sparks upon impact. These features make it play an irreplaceable role in safety-critical fields such as explosion-proofing and marine navigation.

Heat treatment and supply form

Process characteristics

Solution treatment: Rapid cooling at 780 - 820℃ to obtain uniform structure;

Age hardening: Holding at 320 - 340℃ for 3 hours to strengthen the precipitated phases.

Widely applied fields

Thanks to these numerous outstanding properties, beryllium bronze has extensive applications in multiple industrial sectors. From the key springs and elastic components in precision instruments, to the precise gears inside clocks; from the bearings and bushings that operate in high-speed and high-pressure environments, to the welding electrodes, explosion-proof tools and other safety equipment; and even to navigation devices such as marine compasses, beryllium bronze can be found everywhere. It not only enhances the overall performance and service life of products, but also ensures the safety and reliability of equipment.

Challenges Faced

Although beryllium bronze has excellent performance, its high cost has become a major obstacle restricting its wide application. As a rare metal, beryllium is scarce in resources and difficult to extract, which directly leads to the high price of beryllium bronze materials. Therefore, how to reduce production costs and improve resource utilization has become an urgent problem for the beryllium bronze industry to solve.

# Tags:

-

characteristics of beryllium bronze