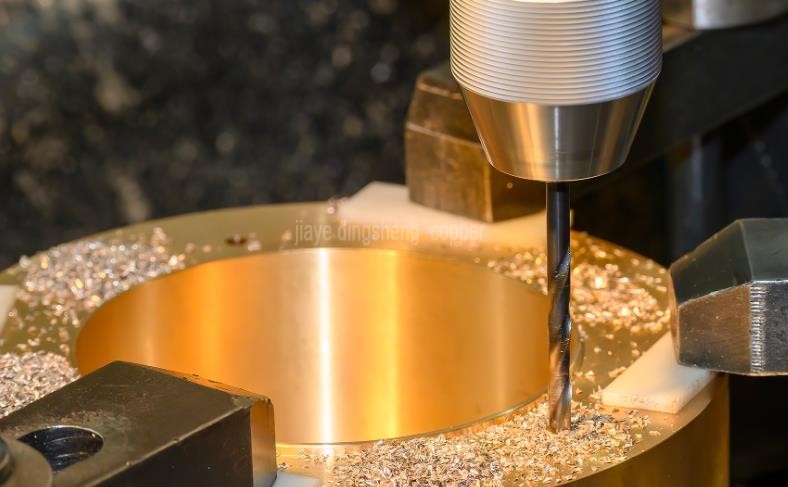

how to punch beryllium copper

Sharing of punch techniques for beryllium copper materials

Can beryllium copper be punched?

Yes. Beryllium copper is a relatively soft metal and is very easy to be perforated. When punch beryllium copper, no excessive force is required; simply select the appropriate drill bit and set the appropriate speed.

Notes for Attention

Beryllium copper is a type of metallic material with excellent electrical conductivity and thermal conductivity, as well as high strength and hardness. Therefore, when punch, the following points should be noted:

1. Determine the diameter and depth of the hole to avoid over-punch or the occurrence of under-drilled holes.

2. Determine the arrangement of the drill bits and the cutting direction, and do not change the cutting direction of the drill bit to avoid vibration and cutting deformation.

3. Cooling liquid should be processed during the punch process.

4. The depth of each punch operation by the drill bit should not exceed half of its diameter.

How to choose the drill bit?

For materials like beryllium copper, they are often relatively fragile and prone to cracking. Therefore, when punch through beryllium copper, we need to select the appropriate drill bit. It is highly recommended to use tungsten steel alloy drill bits, which have high hardness and good wear resistance, can quickly penetrate beryllium copper, and are less likely to be damaged. In addition, the diameter of the drill bit must be selected according to the size of the hole to be drilled. Drill bits that are too large or too small will result in poor punch performance.

How to lubricate?

Lubrication is a very important step before punch, which can reduce the friction of the drill bit, lower the temperature, and increase the lifespan of the drill bit, etc. For materials like beryllium copper, it is recommended to use lithium-based lubricants, as they can effectively reduce the friction coefficient, prevent the drill bit from sticking to the workpiece, and have low environmental pollution and simple operation.

How to control the feed speed of the drill bit?

The feed speed of the drill bit should not be too fast or too slow. If the feed speed is too fast, it is easy to cause the chips not to be cleared in time, resulting in uneven hole walls, cracking, etc. While if the feed speed is too slow, it will accelerate the wear of the drill bit and reduce efficiency. Therefore, it is recommended to control the feed speed of beryllium copper during punch, and adopt different feed speeds for different beryllium copper materials and different drill bit diameters to ensure the quality and efficiency of punch.

How to maintain the punch accuracy?

punch accuracy is the key indicator of punch quality. For materials like beryllium copper, during punch, a stable punch posture should be maintained, the drill bit should not be overly pressed, and the chips should be cleaned regularly to avoid affecting the punch. In addition, the punch tools should also be in good condition, drill bits should be replaced regularly, and they should be cleaned and maintained to ensure the quality and lifespan of the drill bit.

How to prevent cracking and deformation in the punch process?

This material, beryllium copper, is prone to cracking and deformation. Therefore, when punch, the following points should be noted: Firstly, the feed speed should be controlled within an appropriate range and not be too fast; Secondly, the cutting pressure should be reduced. Special attention should be paid to holes with radii smaller than the drill bit's opening; Finally, lubrication should be carried out regularly during the punch process to prevent excessive punch temperature, which may cause deformation and cracking.

The punch of this beryllium copper material is relatively difficult. However, as long as one has certain skills and experience, selects the appropriate drill bit, lubricant, masters the feed speed properly, and pays attention to issues such as punch accuracy, preventing cracking and deformation, etc., this task can be easily accomplished.