how to polish beryllium copper tools

Beryllium Copper Chemical Polishing Process: Detailed Explanation of Application Scope and Operating Steps

At room temperature for 1-3 minutes, the surface of the beryllium-copper tool can achieve mirror-like smoothness and brightness! The key lies in using the original solution, conducting ventilation operations, and cleaning promptly after passivation. Adding 0.5%-1.0% of a long-lasting additive can enhance the glossiness. During the operation, be sure to wear protective equipment. Use a plastic container to hold it, strictly control the number and gap of the workpieces to ensure efficient and safe attainment of a long-lasting polishing effect.

Beryllium-copper is widely used in the fields of electronics and machinery due to its excellent mechanical properties and conductivity. Chemical polishing, as an important means to improve the surface quality of beryllium-copper, the optimization of its process parameters is crucial. This paper conducts experimental research on the Q/YS.102 beryllium-copper chemical polishing solution. Experimental Materials and Methods

(1) Experimental Materials

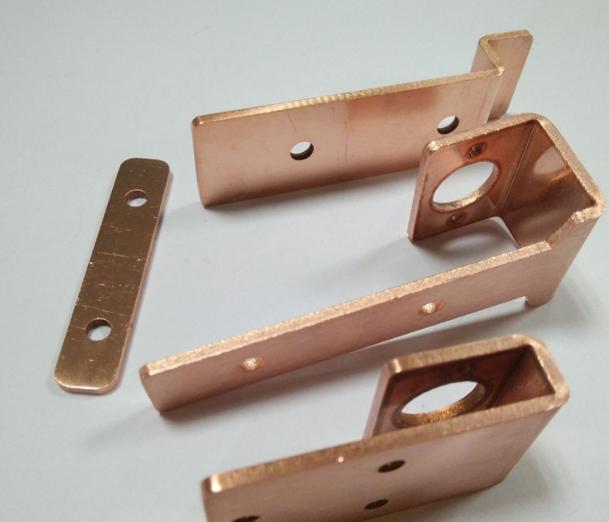

A number of beryllium-copper samples and beryllium-copper chemical polishing solution.

(2) Experimental Methods

Operate according to the product instructions and record the polishing effect of the beryllium-copper surface under different times and conditions.

III. Experimental Results and Analysis

(1) Scope Verification

The experiment shows that this polishing solution is suitable for the chemical polishing and brightening treatment of beryllium copper. After polishing, the copper surface is smooth and shiny, and it can produce mirror-like reflection.

(2) Product Index Analysis

The polishing solution is acidic, with a specific gravity of 1.4 - 1.48, and its appearance is a light yellow transparent liquid. The acidic environment helps remove the oxide layer on the surface of beryllium copper and achieve a bright effect.

(3) Impact of Operating Steps

The use of the original solution, operation at room temperature with ventilation, and polishing time of 1 - 3 minutes have a significant impact on the polishing quality. Cleaning and drying immediately after polishing and passivation can prevent the copper workpiece from changing color again.

(4) Function of Additives

When the copper glossiness does not meet the standard, adding a small amount of long-lasting additives (0.5% - 1.0%) can improve the effect. If the polishing solution is dark green and adding is ineffective, a new polishing agent needs to be replaced.

IV. Precautions

This polishing solution is corrosive. During operation, protection is required to avoid contact with the skin. The working tank for storing the polishing solution should be made of plastic material. The product should be stored in a cool and ventilated place. During polishing, turn the workpiece, and control the number of workpieces and the gap.

The beryllium copper chemical polishing solution shows excellent performance in beryllium copper chemical polishing. By strictly following the operating steps and precautions, high-quality polishing results can be achieved, providing a guarantee for the further processing and application of beryllium copper.

Beryllium copper tools are mainly used in the following fields due to their high strength, wear resistance, and spark-free impact characteristics:

1. Explosion-proof safety tools

Explosion-proof wrench/hammer

Used in flammable and explosive environments such as oil, chemical, and coal mines, it does not produce sparks when impacted, avoiding the risk of igniting dangerous gases.

2. Explosion-proof socket/lever

Used as an alternative to steel tools in power maintenance or oil depot operations, reducing the risk of explosion.

II. Wear-resistant Industrial Components

Mold Inserts and Punches

Injection Mold Inserts: Accelerate heat dissipation, shorten injection cycle

Pressing Mold Punches: High hardness and wear resistance, suitable for automotive body parts (such as doors, airbag shells)

Bearings and Gears

Wear-resistant bearings, sleeves and transmission gears, extend equipment service life

III. Precision Mechanical Components

Electronic Industry Snap Circuits / Connectors

Utilizing high elasticity to manufacture precise contact components with excellent conductivity

Aerospace Components

Corrosion-resistant turbine blades, valve parts, and non-magnetic tools

# Tags:

-

how to polish beryllium copper tools