How to determine the quality and composition of aluminum bronze materials

Aluminum bronze is an alloy mainly composed of copper and aluminum, and is widely used in fields such as aerospace, ships, and instruments and meters. As an important engineering material, determining the material quality and composition of aluminum bronze is particularly crucial. This article will deeply explore from multiple perspectives how to evaluate the material quality and composition of aluminum bronze, helping readers better understand the characteristics and application potential of this material.

The basic composition and characteristics of aluminum bronze

The main components of aluminum bronze are copper and aluminum, with the aluminum content typically ranging from 5% to 12%. Aluminum bronze may also contain small amounts of elements such as iron, manganese, and silicon. Different alloy compositions can affect the properties of aluminum bronze. Common characteristics include:

Excellent corrosion resistance: Aluminum bronze performs particularly well in marine environments and is not easily eroded by chloride ions in the solution.

High strength: It has high tensile strength and yield strength, making it suitable for applications with high loads.

Good machinability: Aluminum bronze has a high hardness, but its machinability is still good, and it is easy to undergo various mechanical processing.

Excellent electrical and thermal conductivity: It is suitable for use in fields requiring good conductivity.

Methods for Judging the Quality of Aluminum Bronze

In the market, the quality of aluminum bronze varies. Here are several methods for judging the quality of aluminum bronze materials:

l 1. Chemical Composition Analysis

Using methods such as spectroscopy analysis and chemical analysis, obtain the detailed chemical composition of aluminum bronze to ensure that the proportions of each component comply with the standards. Applicable standards, such as ASTM B150, can be used to make a more accurate judgment of the material's composition based on these standards.

l 2. Physical Performance Testing

Through tensile tests, hardness tests, etc., evaluate the physical performance of aluminum bronze. These tests help understand the performance of the material in practical applications, such as tensile strength, toughness, etc.

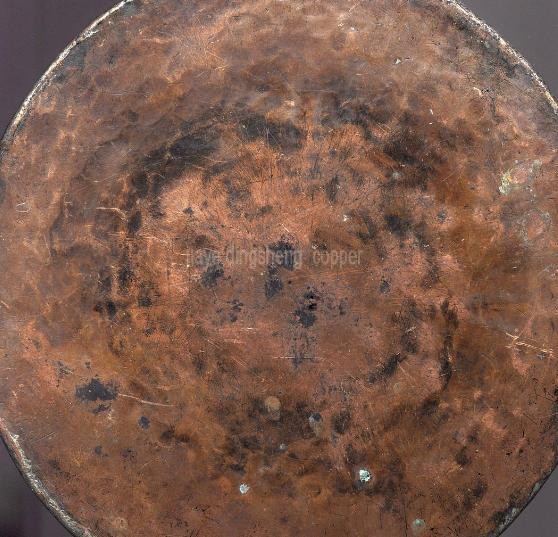

l 3. Visual Inspection

Observe the surface condition of the material. The surface of high-quality aluminum bronze should be smooth, without cracks, and without obvious oxidation phenomena. A magnifying glass or microscope can be used for detailed observation to check for any flaws.

Common aluminum bronze alloy grades and their properties

The different grades of aluminum bronze alloys represent different chemical compositions and properties. Here are some common aluminum bronze grades and their characteristics:

Grade Main Component Main Characteristics

C61000 90% Cu, 10% Al Excellent corrosion resistance, suitable for ships and marine engineering.

C61400 85% Cu, 15% Al, 1% Fe Excellent strength and wear resistance, suitable for mechanical components.

C62800 82% Cu, 18% Al Good conductivity, suitable for electronic device manufacturing.

Applications of Aluminum Bronze

Due to its superior properties, aluminum bronze is widely used in various fields:

Marine Engineering: It is used as a construction material for ships and offshore platforms, thanks to its excellent corrosion resistance.

Aerospace: It is often used to manufacture aircraft components, such as the fuselage and engine parts.

Mechanical Manufacturing: It serves as wear-resistant components for various machinery, such as valves and gears.

Electronic Industry: It is suitable for electrical contact components and connectors.

Suggestions for Selecting Aluminum Bronze Materials

When choosing aluminum bronze materials, consumers should consider the following factors:

Supplier's reputation: Select a supplier with a good reputation to ensure the reliability of material quality.

l Check quality certifications

The supplied materials should have relevant quality inspection reports to ensure compliance and consistency.

l Sample testing

Before large-scale procurement, you can apply for samples for testing to ensure they meet actual requirements.

l Balance of cost and performance

Based on your own needs, reasonably assess the cost budget and find the best balance between performance and price.

Aluminum bronze, as a high-quality engineering material, requires a comprehensive assessment of its quality and composition from multiple perspectives.

# Tags:

-

composition of aluminum bronze materials