Is machining beryllium copper toxic?

During the machining of beryllium copper, toxic metal vapors and dust may be released, thus posing certain toxicity.

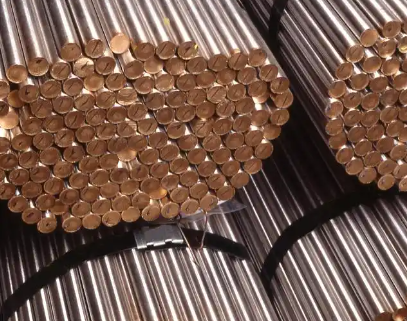

Introduction to beryllium copper

Beryllium copper is a high-strength copper alloy, which is widely used in aerospace and other fields due to its excellent mechanical properties, wear resistance, and corrosion resistance. However, beryllium copper also has certain toxicity because it contains the element beryllium in its composition.

Hazards during beryllium copper machining

1. Metal vapor hazard

During the machining of beryllium copper, high-temperature treatment, brazing, and other operations are often required, which may release beryllium, copper, and other metal vapors and oxides and other harmful gases. In severe cases, it may lead to poisoning and even death.

2. Dust hazard

During the machining of beryllium copper, a large amount of metal dust is produced. If this dust enters the body, it will cause long-term damage to the respiratory system and digestive system.

How to safely process beryllium copper

1. Protective measures

During the machining of beryllium copper, strict protective measures should be taken, such as wearing work clothes, breathing masks, gloves, and goggles, to minimize contact with beryllium copper.

2. Machining environment

In the machining area of beryllium copper, ventilation and air exchange should be improved to reduce the impact of harmful gases and dust released.

3. machining equipment

Protective covers and exhaust devices should be installed on machining equipment to reduce the generation and dispersion of harmful gases and dust.

In conclusion, although beryllium copper has excellent mechanical properties and corrosion resistance, it also has certain toxicity during machining. Therefore, when machining beryllium copper, effective protective measures should be taken to reduce the chance of contact with beryllium copper and protect one's health.

# Tags:

-

Is machining beryllium copper toxic