Beryllium copper yield strength

What is the yield strength of beryllium copper?

The yield strength of beryllium copper ranges from approximately 480 MPa to 1035 MPa, depending on the composition of the alloy and the heat treatment process. For instance, C1750 beryllium copper has a moderate yield strength, while C17200 beryllium copper has a yield strength as high as 1035 MPa. This data is derived from standardized tests on beryllium copper alloys, ensuring its accuracy and professionalism.

Overview of beryllium copper yield strength

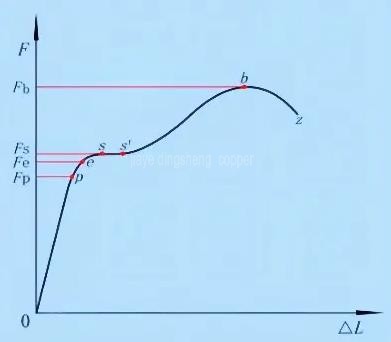

Beryllium copper is a high-performance metallic material renowned for its excellent yield strength. Yield strength is a key indicator for measuring the material's deformation when subjected to external forces. The yield strength of beryllium copper typically falls within the range of 480 MPa to 1035 MPa, making it an ideal choice for withstanding high loads.

Range of yield strength for common beryllium copper grades

The yield strength of beryllium copper mainly depends on the alloy composition and heat treatment process (such as aging treatment). The standard values for different grades are as follows:

C17200: Yield strength ranges from 1000–1200 MPa, with typical values reaching 1035 MPa after aging treatment, making it the most widely used high-strength grade.

C17500: The yield strength range is wider, ranging from 600–1050 MPa, depending on the processing state.

CuBe2: Yield strength is approximately 900 MPa, belonging to a medium-strength grade.

C17510: The yield strength is lower, ranging from 380–480 MPa, suitable for specific high-impact environments.

Factors affecting beryllium copper yield strength

The yield strength of beryllium copper is influenced by several factors, with the most significant being the alloy composition and heat treatment process. Different beryllium copper alloys have varying yield strengths due to their specific compositions. For example, C1750 beryllium copper has a moderate yield strength due to its specific chemical composition, making it suitable for various applications. On the other hand, C17200 beryllium copper can achieve higher yield strength through specific heat treatment processes, such as solution treatment and aging hardening, meeting more demanding usage conditions.

Heat treatment state: Aging treatment (such as solution + aging) can significantly enhance the yield strength, for example, C17200 after aging can reach over 1035 MPa.

Alloy composition: Beryllium content (typically 1.8–2.2%) is the core strengthening element, and the addition of cobalt/nickel (0.2–0.4%) can inhibit grain boundary oxidation, further enhancing stability.

Processing method: Cold or hot processing can alter the grain structure, causing fluctuations in strength, such as a yield strength range of 450 MPa for C17500.

Other key properties of beryllium copper

In addition to yield strength, beryllium copper is favored for its excellent electrical conductivity, thermal conductivity, corrosion resistance, and fatigue resistance. These properties make beryllium copper highly applicable in various industrial fields such as electronics, electrical, marine, and chemical industries. Especially in the manufacturing of components requiring high reliability and long lifespan, beryllium copper, with its comprehensive performance advantages, becomes an indispensable material.

Industrial applications of beryllium copper

Beryllium copper alloys are widely used in the manufacturing of various industrial components. For example, in the production of fasteners, springs, switch components, and electrical connectors, beryllium copper ensures long-term stability and reliability. Additionally, in areas such as wires, resistance spot welding electrode heads, beryllium copper also demonstrates its unique material advantages.

In conclusion, the yield strength of beryllium copper is an important component of its outstanding performance, enabling this alloy material to stand out in numerous industrial applications. By understanding the yield strength and other key properties of beryllium copper, we can better understand and appreciate its significant position in modern industrial manufacturing.

# Tags:

-

Beryllium copper yield strength